Frac hits are also called “communication events.”

Chemical company offers solution to ‘frac hits’ by Mella McEwen, Jan 16, 2020, Reporter-Telegram

It’s an issue Permian Basin oil and gas operators have been grappling with as they drill wells in tighter and tighter quarters: How to keep hydraulic fracturing of the newer or “child” wells from interfering or damaging the older or “parent” wells or being damaged themselves?

“It’s a dire problem,” Eric Foster, chief executive officer of TenEx Technologies, said in a phone interview. He said that over the next couple of years, domestic oil and gas production will begin to decline “because drillers can’t drill enough wells” to offset the lower productivity of damaged parent wells or the child wells.

“As competitive as the industry is, companies recognize the existential threat this is, especially in the Permian Basin,” he said.

“If we don’t come up with a solution, the Permian Basin could lose its place as the top producing region in the world. There’s good acreage that can’t be tapped because of the frac hit problem.”

“The industry is desperate to find better strategies to protect the parent wells and get more production from the child wells,” he said.

Rystad, the energy consulting service, estimates that only 20 percent of the wells drilled in the Permian Basin in the third quarter of last year were parent wells.

Foster’s Philadelphia-based oilfield chemical company is offering a chemical solution, as opposed to a mechanical solution. NoHIT is designed to be pumped as an additive to a parent well’s preload or active loading program.

[Some solution. More toxic chemicals intentionally injected into our environment. Are they out of their sodding greedy minds?]

“Our product involves the injection of a chemical solution that includes aluminum,” Foster said. “Then we inject an activator, which will vary depending on the characteristics of the well. That activator will change the pH of the water in the well and cause the aluminum to react, stripping the hydrogen off the water and generating hydrogen gas.”

That gas pressurizes the depleted rock and increasing associated rock stress, discouraging child well fractures from communicating with the parent well fractures. That not only protects the parent well but encourages the fractures in the child wells to target new reservoirs, Foster said.

To address the problem, some operators inject gas – which can be expensive — while other companies shut in the well for a period of time to let the reservoir build up pressure, he said. Others preload the well with water.

He described the Permian Basin as “thirsty ground with big wells that take an ocean of water to fill every nook and cranny. I just need enough water that the aluminum will react. I just need a small lake, not an ocean.” [That’s still terrible]

Foster said he believes NoHIT it will improve the capital structure of his customers.

He used the example of a producer who based his reservoir value on density of 100 wells but could only drill 50 because the communication between wells impaired production.

“You’ve reduced your reservoir value 50 percent,” he said. “This is almost a live-or-die problem. If we and others can help restore reservoir value by restoring density, that helps the bottom line.” [While destroying the subsurface, contaminating groundwater and poisoning communities and families, wildlife, pets and livestock. Vulgar human greed-induced insanity.]

There is a cost to his product, he acknowledged. “But when you spent $7 million on a well, how much is it worth to not wreck it?” he said. [ But, when is the toxic pollution of our global environment enough?]

The technology has worked well in the lab, and Foster said he is anxious to get it in the ground. It will be used for the first time by the end of February, he said.

The company has been in talks with producers in several producing basins, including in the Niobrara, Eagle Ford and in Calgary, Alberta, but he said it is “strongly focused on the Permian Basin.”

He wants companies “to talk to us about how they would experiment with our product,” and urges collaboration to find solutions.

Refer also to:

Encana’s Supersize Spatial Intensity Frac Cube Experiment Fails

It can get pretty testy. Encana fracked somebody else’s well – in yet another case of “involuntary stimulation”

2013 08 05: When 2 wells meet, spills can often follow

Canada steps up well monitoring to try to avoid ‘frack hits’

2013: Alberta company prevents environmental fracking disasters by Surface Solutions Inc.

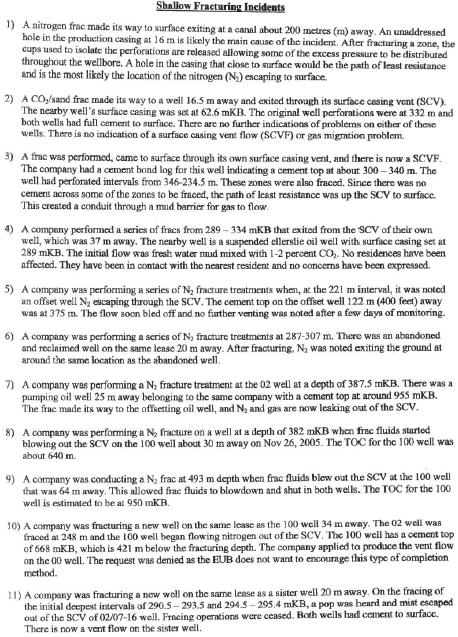

A “frac” can go horribly wrong when there is a “communication” communication breakdown during the process to one or more neighboring wells. A communication breakdown means the fracking well is causing a disturbance with a non-fracking well. The majority of oil companies fracking in Alberta do not currently monitor their frac jobs. If the downhole pressure reaches a point to create “communication” with other wells. The result can be environmentally and financially disastrous, blowing off wellheads, contaminating water sources, spilling frac fluid and oil all over other well site leases.

The ERCB admitted that 21 deep frac communication events had occurred in 2012 alone:

Curran says that since the ERCB began monitoring interwellbore communication this year, there have been 21 incidents, but they rarely cause damage.

ERCB: New rules coming for fracking and unconventional resources Fast Forward Weekly

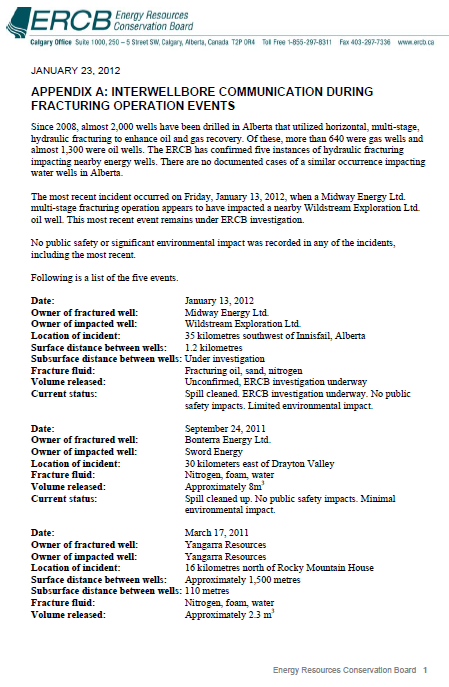

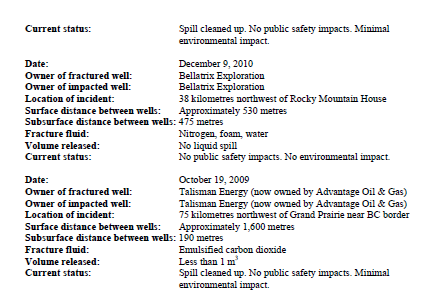

2012: ERCB (now AER) Appendix A: Interwellbore Communication During Fracturing Operation Events

Surface distance between wells: 1.2 kilometres

Subsurface distance between wells: Under investigation…

Surface distance between wells: Approximately 1,500 metres

Subsurface distance between wells: 110 metres…

Surface distance between wells: Approximately 530 metres

Subsurface distance between wells: 475 metres…

Surface distance between wells: Approximately 1,600 metres

2010: BC OGC Safety Advisory 2010-03 Communication during fracture stimulation

Fracture propagation via large scale hydraulic fracturing operations has proven difficult to predict. Existing planes of weakness in target formations may result in fracture lengths that exceed initial design expectations.

2013 02 19: FOIP letter from AER (previously ERCB) on all fracks gone bad in Alberta

2013 04 02: Alberta company prevents environmental fracking disasters

A “frac” can go horribly wrong when there is a “communication” breakdown during the process to one or more neighboring wells. A communication breakdown means the fracking well is causing a disturbance with a non-fracking well. The majority of oil companies fracking in Alberta do not currently monitor their frac jobs. If the downhole pressure reaches a point to create “communication” with other wells. The result can be environmentally and financially disastrous, blowing off wellheads, contaminating water sources, spilling frac fluid and oil all over other well site leases.

Like this?

Trying to clean up the ERCB’s reputation (plagued with scandals and the Ernst lawsuit), it’s spots were changed to the AER. Spot removal included legally removing public interest from the regulator’s mandate.

January 13, 2012: Frack hit on farm near Innisfail, Alberta. Photos by Alberta Surface Rights Group

2012 12 18: Fracking blowout report released by ERCB

2012 01 23: ERCB (now AER): Interwellbore Communication During Fracturing Operation Events

2010 03: BC OGC Safety Advisory 2010-03 Communication during fracture stimulation

Fracture propagation via large scale hydraulic fracturing operations has proven difficult to predict.

2006 01 31: Directive 027: Shallow Fracturing Operations-Interim Controls

Information provided by industry to date shows that there may not always be a complete understanding of fracture propagation at shallow depths and that programs are not always subject to rigorous engineering design.

2006 01 27: Directive 027: Shallow Fracturing Operations-Interim Controls

Increased development at ever shallower depths.

Increased Fracture volumes, rates and pressures.

Increased public concern on water well protection.

Lack of regulatory control on fracture design. …

Number of reported incidents of communication at nearby EUB licenced wells

~2004/2005: Shallow “Involuntary Stimulation” events, from EUB (ERCB/AER) library: