Emily Sanders@emdashsanders:

learning more about CO2 pipeline leaks has revealed some of the scariest shit I have encountered and I write about climate disinformation for a living. the majority of the public is not concerned enough about this including me a week ago

@GreyHairOpsGuy:

No kidding CO2 pipeline leaks keep me up at night too. CO2 kills everything

***

Exxon/Denbury CO2 Pipeline Leaks in Louisiana, Triggering Shelter in Place Order by Mark Hefflinger, April 5, 2024, Pipeline Fighters

Update 4/19/24:

The Guardian published the first substantial on-the-ground coverage from the April 3 incident, sixteen days later on April 19: “‘Wake-up call’: pipeline leak exposes carbon capture safety gaps, advocates say“. The reporting by Nina Lakhani from Sulphur, Louisiana where the incident occurred revealed previously unknown key details, such as the CO2 leak was first discovered by neighbor Holly McGee, who told the Guardian “she reported the leak to the sheriff’s office around 6pm on 3 April – after calls to the company went unanswered.”

McGee told the Guardian, “the leak sounded like a pressure cooker, and smelt like chemicals.”

“This wasn’t like the usual gas release that we see from time to time, this went on for a long time. I knew we should leave,” McGee, who evacuated to her grandparents home two streets away where they could still hear the CO2 leaking, told the Guardian. “If it had not been so windy, it could have been worse. We know what happened in Mississippi … I am more vigilant now.”

According to the Guardian’s reporting:

- “Interviews by the Guardian suggest that no pipeline operator was on site at the pump station where the leak occurred – and the camera monitoring the facility was not working. Exxon staff located 50 miles away in Beaumont, Texas, learned about the leak after it was reported to emergency services, the Guardian understands. It took more than two hours for an operator to arrive at the facility and fix the leak, according to the local fire department.”

- “Earlier this week, the Guardian observed contractors carrying out anti-corrosion maintenance work at the pump station, where a significant leak was previously reported in 2011.”

Pipeline companies routinely — including Summit Carbon Solutions and the defunct Navigator CO2 Ventures — publicly tout their “24/7 control room” with “the latest in leak detection technologies” to monitor for pipeline ruptures. Evidence from the Exxon/Denbury CO2 pipeline rupture on April 3, and countless other historical ruptures on oil, gas and other pipelines, shows that “neighbors” — oftentimes farmers, or even children out exploring, discover these pipeline accidents before the companies’ “early warning systems” or even local first responders.

Screenshot: Summit Carbon Solutions

State Journal-Register

Update 4/11/24:

The National Response Center has published the initial report of the CO2 pipeline accident, including timing and estimated spill volume: at 6:18 p.m. CT on Wednesday, April 3, 2,548 barrels or 107,016 gallons (6.34 MMFCS in gas quantity) of CO2 were released over the course of the next two hours, until the final valve was closed at 8:22 p.m. The CO2 gas spread widely enough into the surrounding area that the Calcasieu Parish Police Jury issued a shelter-in-place order from around 6:30 p.m. until 9:16 p.m. for a quarter-mile radius in the neighborhood where the leak took place at Exxon/Denbury Resources’ Lake Charles Pumping Station near Sulphur, La. The U.S. Dept. of Transportation’s Pipeline and Hazardous Materials Safety Administration (PHMSA) and local police department were initially notified by whomever on the scene called to make the initial report to the National Response Center, and an investigation “assumed cause is due to an O Ring failure on the launcher pig trap door. Investigation is still underway.”

FULL TEXT OF NATIONAL RESPONSE CENTER REPORT:

“UPDATED INFORMATION IS AS FOLLOWS:

CHANGED THE INCIDENT TYPE FROM FIXED TO PIPELINE. THE RELEASE IS SECURED. THE RELEASE STARTED AT 18:18 PM CENTRAL TIME, AND THE FINAL VALVE WAS CLOSED AT 20:22 PM CENTRAL TIME.

RELEASED QUANTITY OF CARBON DIOXIDE IS 2548 BARRELS (6.34 MMFCS IN GAS QUANTITY).

ASSUMED CAUSE OF THE LEAK IS DUE TO AN O RING FAILURE ON THE LAUNCHER PIG TRAP DOOR. INVESTIGATION IS STILL UNDERWAY.

PHMSA AND LOCAL PD HAVE BEEN NOTIFIED.

ORIGINAL REPORT:

CALLER IS REPORTING THERE IS A RELEASE OF C02 (CARBON DIOXIDE) INTO THE ATMOSPHERE FROM PUMP STATION DUE TO UNKNOWN CAUSES AT THIS TIME.”

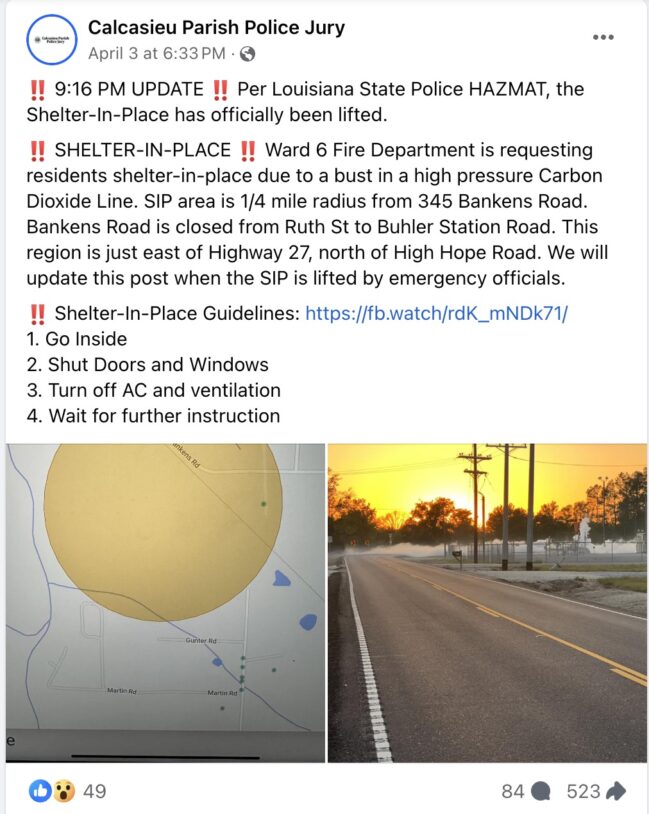

A pipeline operated by Exxon-owned Denbury carrying highly-pressurized carbon dioxide (CO2) experienced a “leak” on Wednesday, April 3 that caused a release of CO2 that prompted a shelter-in-place order to be issued near the town of Sulphur, Louisiana.

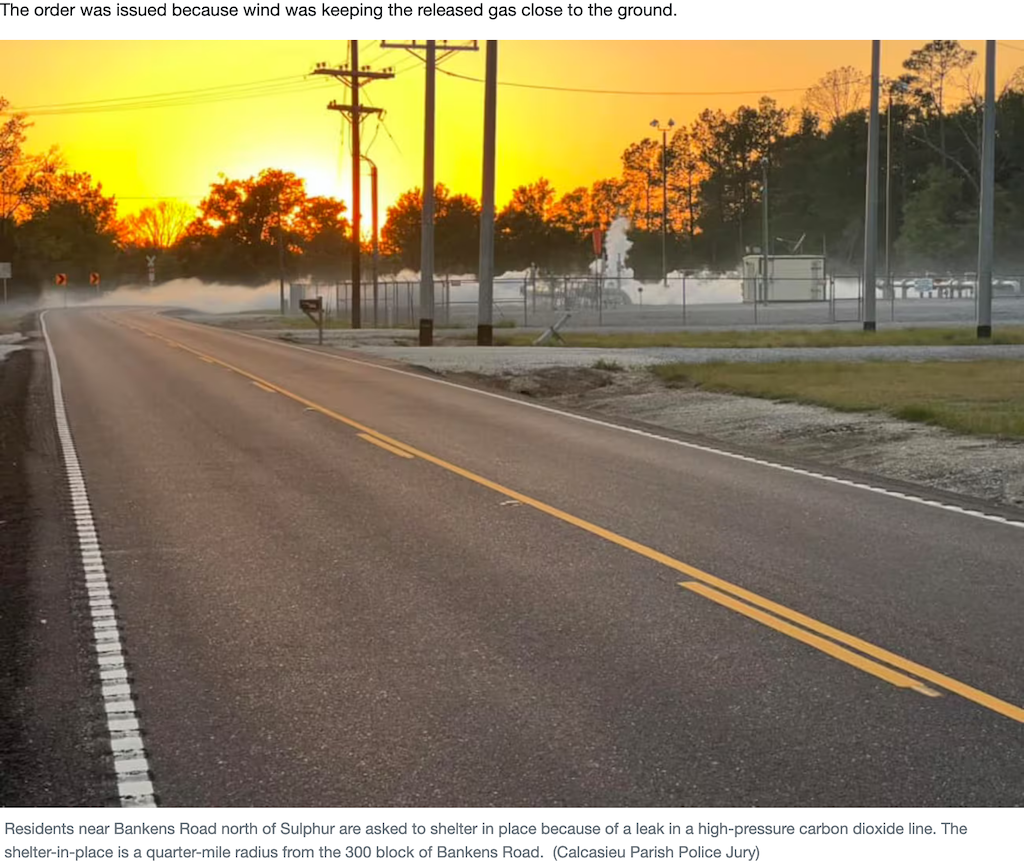

Local TV station KPLC reported that “Calcasieu emergency preparedness officials said the Denbury pipeline was blocked off around 8:25 p.m. and the shelter-in-place order lifted shortly after. The order was issued because wind was keeping the released gas close to the ground.”

The shelter-in-place order was issued for the area within a quarter-mile radius from the 300 block of Bankens Road, where a Denbury pump station for the pipeline is located in a rural neighborhood, surrounded by homes. It was later confirmed by the U.S. Dept. of Transportation’s Pipeline and Hazardous Materials Safety Administration (PHMSA), who are reported to be on site and investigating along with the company, according to the Pipeline Safety Trust — that the leak took place at Exxon/Denbury’s Lake Charles Pumping Station for Denbury’s 24-inch Green Pipeline.

The incident was reported to the National Response Center (NRC) as being associated with the pump station’s “smart pig launcher site.” The NRC reports a possible “O-ring” or seal failure, as potential incident causation. A “smart pig (Pipeline Inspection Gauge)” is a tool used to examine a pipeline’s integrity by being placed in the interior and running sensors and cameras along the pipe’s length (View animation of a pipeline pig launcher).

At this stage in its investigation, PHMSA said the smart pig launcher site is isolated and there is no ongoing threat, according to the Pipeline Safety Trust. PHMSA’s investigation is ongoing, and to this point there has still been no estimated volume of CO2 released to be publicly disclosed.

***

Dr. Sandra Steingraber @ssteingraber1:

Why no one wants to live near pipelines ferrying high pressure liquid CO2. Yesterday in Louisiana (and were it not for the wind, this would almost certainly would have been much worse):

Shelter-in-place lifted north of Sulphur after pipeline leak stopped by KPLC Digital Team, Apr. 3, 2024

SULPHUR, La. (KPLC) – A shelter-in-place has been lifted for residents near Bankens Road north of Sulphur after a leak was stopped in a high-pressure carbon dioxide line.

Calcasieu emergency preparedness officials said the Denbury pipeline was blocked off around 8:25 p.m. and the shelter-in-place order lifted shortly after.

The order was issued because wind was keeping the released gas close to the ground.

Dr. Sandra Steingraber @ssteingraber1:

“The frigid temperature of released high-pressure CO2 also makes steel pipelines brittle, allowing a small rupture to quickly unzip.”

Gibson City, IL (near where I grew up) is alarmed:

Carbon capture project sparks concern in rural Illinois

Refer also to:

2023: Sneaky dirty rotten frac’ers: “Southern Tier CO2 to Clean Energy Solutions LLC” attacks New York State’s Frac Ban, tries to con landowners into getting frac’d with CO2 under guise of being clean.![]() Imagine the insanity of frac’ing in densely populated areas with deadly CO2? It doesn’t stay put, industry ought not be allowed to inject it anywhere, especially not under guise of reducing pollution (which is really just code for making taxpayers pay for continued oil and gas development and enhanced recovery).

Imagine the insanity of frac’ing in densely populated areas with deadly CO2? It doesn’t stay put, industry ought not be allowed to inject it anywhere, especially not under guise of reducing pollution (which is really just code for making taxpayers pay for continued oil and gas development and enhanced recovery).![]()

LEFT: The CO2 pipeline rupture. RIGHT: Vehicles pass over the pipeline explosion site in Satartia in July. Yazoo County Emergency Management Agency/Rory Doyle for HuffPost

2012: CO2 in Stream, Dead Ducks Prompt Wyo. DEQ Citation against Anadarko

The leak happened in an area where CO2 is injected underground to help revive an old oil field and boost oil production. The Wyoming Department of Environmental Quality has ordered Anadarko Petroleum to identify and control the carbon dioxide leak into Castle Creek in central Wyoming. The Casper Star-Tribune reports…DEQ also is telling Anadarko to monitor the stream’s acidity until three consecutive tests show normal pH. A state violation notice says company officials identified a nearby carbon dioxide injection well as the possible source of the leaking gas. Anadarko spokesman Dennis Ellis says Anadarko hasn’t yet verified where the gas originated.

2012: Peer reviewed PNAS paper: Earthquake triggering and large-scale geologic storage of carbon dioxide

Despite its enormous cost, large-scale carbon capture and storage (CCS) is considered a viable strategy for significantly reducing CO2 emissions associated with coal-based electrical power generation and other industrial sources of CO2. … We argue here that there is a high probability that earthquakes will be triggered by injection of large volumes of CO2 into the brittle rocks commonly found in continental interiors. Because even small- to moderate-sized earthquakes threaten the seal integrity of CO2 repositories, in this context, large-scale CCS is a risky, and likely unsuccessful, strategy for significantly reducing greenhouse gas emissions

2012: The evaluation of CO2-based vapour extraction (VAPEX) process for heavy-oil recovery

Vapor extraction (VAPEX) has been proposed as an alternative for heavy-oil recovery in reservoirs where thermal methods face technical and economic problems. In VAPEX, a pair of horizontal injector-producer wells is employed. The gaseous hydrocarbon solvent (normally propane or a mixture of methane–propane or propane–butane) is injected from the top well and the diluted oil drains downward by gravity to the bottom producer. Recently, the idea of incorporation of CO2 into the gaseous hydrocarbon mixture has emerged. Incorporation of CO2 is believed to make the process more economical and environmentally and technically attractive. … The objective of this work, therefore, is to simulate the performance of the VAPEX process when different solvent mixtures, including hydrocarbon gases and CO2, are incorporated with the aim of improving its performance.

2008: Bachu, S., Buschkuehle, B.E., Haug, K. and Michael, K. (2008): Subsurface characterization of the Edmonton-area acid-gas injection operations; Energy Resources Conservation Board, ERCB![]() Now AER

Now AER![]() /AGS Special Report 92, 134 p.

/AGS Special Report 92, 134 p.

… From Page 88:

Figure 59 shows the extent of the Acheson original Blairmore T and subsequent St. Albert-Big Lake Ostracod A pools, and of the Strathfield (undefined) gas reservoir in the context of lithofacies changes in the Lower Mannville Basal Quartz and Ellerslie formations. When approval was granted for acid gas injection at Acheson, the regulatory agency required the operator to file annually with EUB and each other operator in the Acheson Blairmore T and St. Albert-Big Lake Ostracod A pools progress reports that “shall include the impact of acid gas injection on the performance of offsetting producing wells”. In March 2004 the operator at Acheson reported that CO2 was detected in 2003 in well 10-22-53-26W4 in the St. Albert-Big Lake Ostracod A pool, located at 3,625 m north from the acid-gas injection well. No H2S has been detected in the produced gas. Since at Acheson the average composition of the acid gas is 87% CO2 and 11% H2S (Table 14), with H2S being denser and more viscous than CO2, it is expected that CO2 would show first at a producing well. In addition, diagenetic processes within the reservoir could have reduced the H2S concentration in the injected acid gas as a result of pyrite precipitation, if an iron source was available. The issue was brought to EUB’s attention and was heading to a hearing, but the operator at Acheson has indicated to the regulatory agency that it has initiated an Appropriate Dispute Resolution process with the operator of the offset producing well to address the issue of CO2 breakthrough, and that this situation “will be addressed pursuant to the terms of the Mediated Settlement Agreement”.![]() To gag the harmed?

To gag the harmed?![]()

This case shows that, after 13 years of injection, CO2 has migrated northward a distance of [nearly 4 km] mostly under the combined drive of injection and production.

The drive into the St. Albert-Big Lake Ostracod A gas pool has increased lately with the large spike in gas production from this pool (Figure 57b). There are five producing wells much closer to the acid-gas injection well (Figure 59) that did not report CO2 breakthrough, but these wells are owned by the same operator that operated until recently the Acheson acid-gas injection site. If acid gas broke through at any of these wells, it is most likely that the operator just stripped the acid gas from the sour reservoir gas and re-injected it, as the produced gas in this area is sour to begin with. Understanding the migration path and fate of the injected acid gas at Acheson requires a separate study that is beyond the scope of this report. …

2007: Presentation on above 2006 paper Factors Affecting or Indicating Potential Wellbore Leakage by Watson and Bachu at the Alberta regulator, AER (when it was EUB), no less!

2006 May: The Role of the Upper Geosphere in Mitigating CO2 Surface Releases in Wellbore Leakage Scenarios

2006 June: Possible indicators for CO 2 leakage along wells by Bachu and Watson, 8th International Conference on Greenhouse Gas Control Technologies, Trondheim, Norway

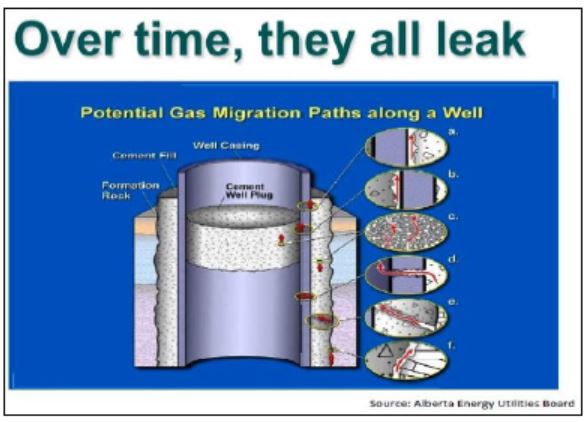

… Storage safety refers to the potential harm to other resources, equity and life that a CO2 leak may entail.

The probability and effects of leakage from CO2 storage sites need assessment by both the operator and regulatory agency during the application and permitting process, during the operational phase and after site abandonment [3].

Any fluid in the subsurface, especially a buoyant one like CO2, will migrate laterally within the injection unit and may leak upwards across formations through faults and fractures and/or defective wells [1, 4].

The potential for CO2 leakage through fractures and faults can be well managed through proper geological characterization and selection of the storage site, and through proper operating procedures.

Managing the potential for CO2 leakage through wells is more difficult.

Exploration and production wells have been drilled, completed and abandoned since the middle of the 19th century, with variable technology and materials, and with no or under variable regulatory regimes. Well materials (cements, steel, elastomers, etc.) will or may degrade over time, particularly in the presence of corrosive agents such as saline formation water and CO2 [5, 6]. Thus, the potential for leakage through existing wells needs to be assessed for site selection and remediation. New wells will also be subjected to the same in-situ conditions as the existing wells.![]() Dr Tony Ingraffea subsequently found new wells to be worse leakers than older ones, which makes sense given the oil and gas industry’s relentless greed, lies, and demanding deregulation which has been consistently granted by our deregulators, notably Alberta’s “No Duty of Care” legally immune bullying shameless AER.

Dr Tony Ingraffea subsequently found new wells to be worse leakers than older ones, which makes sense given the oil and gas industry’s relentless greed, lies, and demanding deregulation which has been consistently granted by our deregulators, notably Alberta’s “No Duty of Care” legally immune bullying shameless AER.![]() …

…