In Illinois, a massive taxpayer-funded carbon capture project fails to capture about 90 percent of plant’s emissions by Brendan Gibbons, April 25, 2024, Oil and Gas Watch

Last year, the Department of Energy’s National Energy Technology Laboratory celebrated what it called “the largest demonstration of its kind in the United States” at an ethanol plant in Decatur, Illinois, where carbon dioxide (CO2) is being captured and permanently stored deep underground.

The project, a partnership among ethanol producer Archer Daniels Midland, oilfield service company Schlumberger, the Illinois State Geological Survey, and Richland Community College, received $281 million in taxpayer dollars via Department of Energy grants. According to the department, it has stored more than 2.8 million metric tons of CO2 since 2011; EPA records put the figure at 3.94 million metric tons. In a January 2023 article, Energy Department officials said the project “marks a crucial step forward in efforts to decarbonize the U.S. economy and power sector by 2050.”

However, EPA records also show that the plant over the last decade has captured only 10-12 percent of the plant’s emissions each year at most, allowing the rest of the carbon dioxide to escape into the atmosphere. This raises questions about whether industrial-scale carbon capture technology can be a meaningful solution to global warming.

Whether carbon capture will work became an even more burning issue this week, when new EPA regulations for coal-powered power plants emphasized carbon capture as potential solution to keep coal plants open.![]() Keep polluting – that’s the goal of CCS, not whether it’ll ever work or not. Second goal is to steal the public’s money from health and education, to give to multi-billion dollar profiting oil, gas, bitumen and coal polluters.

Keep polluting – that’s the goal of CCS, not whether it’ll ever work or not. Second goal is to steal the public’s money from health and education, to give to multi-billion dollar profiting oil, gas, bitumen and coal polluters.![]()

William Burns, founding co-director of the Institute for Responsible Carbon Removal American University and a visiting professor at Northwestern University, noted that even the modest amount of CO2 stored at the ADM plant in Illinois was only achieved with the help of massive taxpayer subsidies.

“We’ve been providing these subsidies for a long time – billions and billions of taxpayer dollars – and we still have very little to show for it,” Burns said.

The Archer Daniels Midland (ADM) plant in Decatur, Illinois, was the first large-scale industrial facility in the U.S. to permanently store CO2 underground. Since 2011, the plant has captured CO2 from its ethanol production plant, which turns corn into a fuel additive for vehicles. The facility injects the CO2 into a sandstone formation saturated with saltwater hundreds of feet below ground.

This permanent underground CO2 storage is in contrast to injecting captured CO2 underground to force out more oil, the most common form of carbon capture and reuse called “enhanced oil recovery.” ADM officials and carbon sequestration advocates argue that permanent carbon storage projects like this are needed to bring greenhouse gas emissions down to net zero, which is required to stave off the worst effects of climate change.

Companies are planning to deploy the same technology in use at ADM’s Decatur plant across the U.S. A report last week by the Congressional Research Service shows that there are 130 pending applications nationwide to drill carbon disposal wells for permanent geologic storage of CO2. Another 33 applications are under review in Louisiana, North Dakota, and Texas, where the EPA has given the states authority to issue permits.

However, few examples of large-scale industrial CO2 storage projects currently exist. Of the 13 carbon capture projects that reported to EPA in 2022, a majority – seven plants – injected captured CO2 back into the ground for enhanced oil recovery. Four injected carbon into the ground with waste produced by gas processing plants as a waste disposal method. Only two plants (including the ADM plant) were not part of the oil and gas industry, and injected CO2 into the ground for permanent sequestration. The other is the Red Trail Energy biofuel plant in Stark, North Dakota.

As the EPA and state regulators consider approving more of these projects, the federal government is pouring billions in grants and tax subsidies into carbon capture, including the $281 million in grants for the ADM project. (This does not include tax breaks for which the plant likely qualifies.)

The small percentage of carbon captured by ADM undercuts the argument that industrial carbon capture can have a significant impact on global warming. Skeptics describe carbon capture as a false solution that will never be deployed on a big enough scale to meaningfully reduce CO2 emissions. Former Vice President Al Gore, for example, called carbon capture technology a “fraud” during an April 12 speech to environmentalists.![]() Of course it’s a fraud, industry, regulators and politicos know it.

Of course it’s a fraud, industry, regulators and politicos know it.![]()

The Decatur plant is the largest agricultural facility source of CO2 emissions in the U.S., emitting at least 4.1 million metric tons per year over recent years, according to EPA records. While the company captures and stores some of its CO2 – ranging from 428,580 to 525,002 metric tons per year since 2017 – this only amounts to about 10-12 percent of the company’s annual facility-wide emissions.

Archer Daniels Midland is also short of its initial goal to sequester 2,000 to 3,000 metric tons of CO2 per day. From 2017 to 2022, the plant stored an average of about 1,345 metric tons per day, which is less than half to two thirds of the project’s goals.

EPA records also show that a monitoring well at the ADM facility leaked 307 tons of CO2 in 2022, amounting to 0.07 percent (or 307 tons) of the carbon stored that year.

Though some experts hope the carbon storage industry can succeed, others say the small percentage of emissions captured – even more than a decade into the project – is raising questions about the effectiveness of the technology.

Charles Harvey, an MIT professor who once worked for a carbon capture startup firm and became skeptical about the cost-effectiveness of the technology, questioned the benefit of sequestering carbon at an ethanol plant in the first place. Some studies have shown that ethanol blended with gasoline is worse for the climate than straight gasoline because of the vast amounts of land needed to grow corn to produce it, plus emissions from making it and burning it in vehicles.

“If our interest is in using government resources to reduce CO2 emissions, that money would be much better spent not making ethanol,” Harvey said. “You’d really be better off just replacing those corn fields with solar panels. You’d get a lot more reduction, and you get cheaper electricity.”

The Archer Daniels Midland facility in Illinois has fared better than most other carbon capture projects around the world. Though the technology has been around since the 1970s, most projects have failed. According to one 2020 review, of the 149 projects intended to be storing CO2 by 2020, more than 100 have been terminated or placed on indefinite hold, largely due to financial problems.

However, Anthony Kovscek, a professor of energy science and engineering at Stanford University, called the ADM project a “great test case.” One lesson scientists learned, he said, was how to inject CO2 underground without triggering earthquakes. “As far as I have seen, there have been very few operational issues of note and certainly no leakage of CO2 to the surface,” Kovscek said.

Sally Benson, an energy science engineering professor at Stanford University and former director of the Global Climate and Energy project, said the carbon capture industry is still in its “early days” but called it “a very important technology.”![]() Pffffft. Decades is too long; life on earth doesn’t have decades, nor does earth benefit from more con jobs enabling more pollution to be dumped into the atmosphere. CCS is only important as a legalized money laundering tool – steal from the poor, to give to the rich.

Pffffft. Decades is too long; life on earth doesn’t have decades, nor does earth benefit from more con jobs enabling more pollution to be dumped into the atmosphere. CCS is only important as a legalized money laundering tool – steal from the poor, to give to the rich.![]()

“Every bit of CO2 we put up into the atmosphere leads to more warming, and we’re running out of time,” Benson said. “This is a technology at hand that gives us yet another tool, in addition to renewables and so forth, to begin to reduce our emissions.”![]() Bullshit. CCS only increases pollution by enabling more and more pollution.

Bullshit. CCS only increases pollution by enabling more and more pollution.![]()

Refer also to:

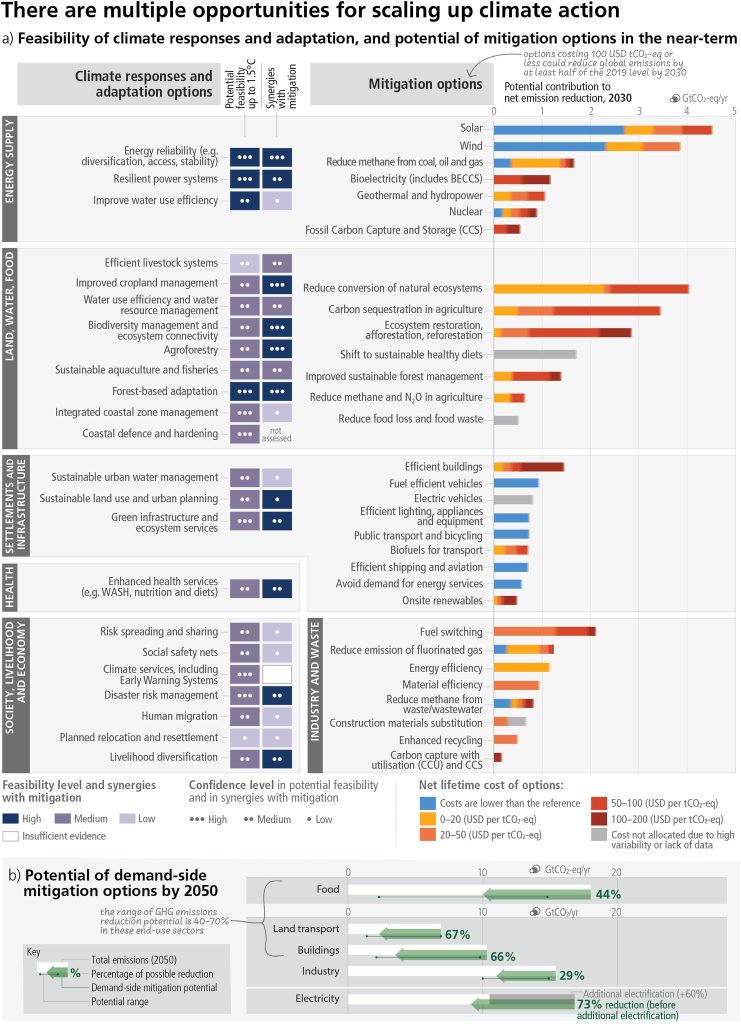

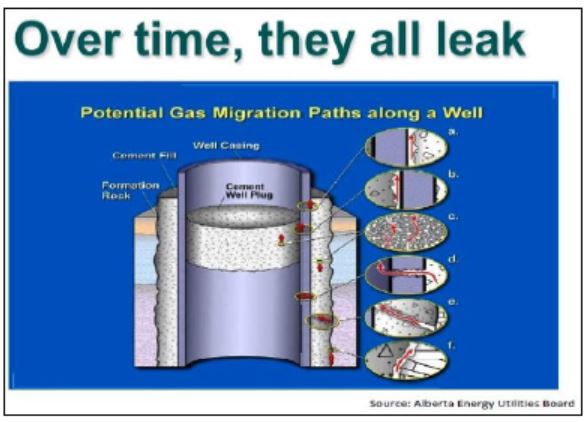

2023: IPCC climate mitigation chart, note CCS at the very bottom, with highest cost and lowest return:

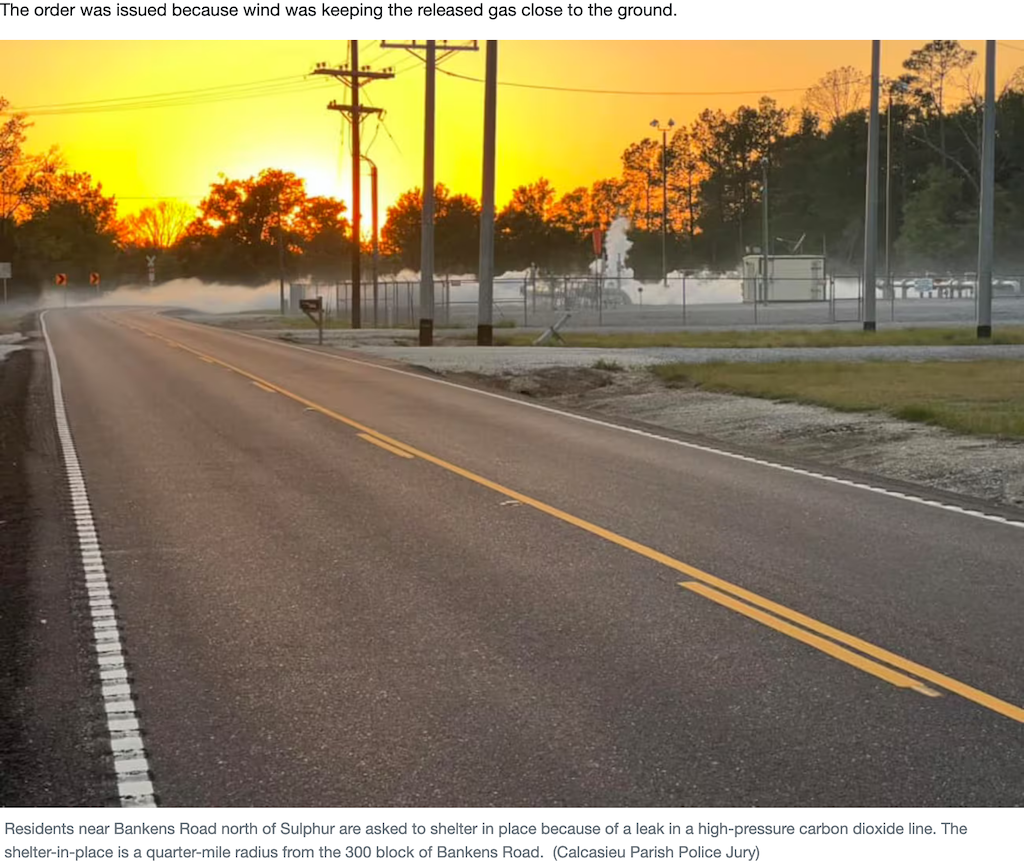

LEFT: The CO2 pipeline rupture. RIGHT: Vehicles pass over the pipeline explosion site in Satartia in July. Yazoo County Emergency Management Agency/Rory Doyle for HuffPost

2012: CO2 in Stream, Dead Ducks Prompt Wyo. DEQ Citation against Anadarko

The leak happened in an area where CO2 is injected underground to help revive an old oil field and boost oil production. The Wyoming Department of Environmental Quality has ordered Anadarko Petroleum to identify and control the carbon dioxide leak into Castle Creek in central Wyoming. The Casper Star-Tribune reports…DEQ also is telling Anadarko to monitor the stream’s acidity until three consecutive tests show normal pH. A state violation notice says company officials identified a nearby carbon dioxide injection well as the possible source of the leaking gas. Anadarko spokesman Dennis Ellis says Anadarko hasn’t yet verified where the gas originated.

2012: Peer reviewed PNAS paper: Earthquake triggering and large-scale geologic storage of carbon dioxide

Despite its enormous cost, large-scale carbon capture and storage (CCS) is considered a viable strategy for significantly reducing CO2 emissions associated with coal-based electrical power generation and other industrial sources of CO2. … We argue here that there is a high probability that earthquakes will be triggered by injection of large volumes of CO2 into the brittle rocks commonly found in continental interiors. Because even small- to moderate-sized earthquakes threaten the seal integrity of CO2 repositories, in this context, large-scale CCS is a risky, and likely unsuccessful, strategy for significantly reducing greenhouse gas emissions

2012: The evaluation of CO2-based vapour extraction (VAPEX) process for heavy-oil recovery

Vapor extraction (VAPEX) has been proposed as an alternative for heavy-oil recovery in reservoirs where thermal methods face technical and economic problems. In VAPEX, a pair of horizontal injector-producer wells is employed. The gaseous hydrocarbon solvent (normally propane or a mixture of methane–propane or propane–butane) is injected from the top well and the diluted oil drains downward by gravity to the bottom producer. Recently, the idea of incorporation of CO2 into the gaseous hydrocarbon mixture has emerged. Incorporation of CO2 is believed to make the process more economical and environmentally and technically attractive. … The objective of this work, therefore, is to simulate the performance of the VAPEX process when different solvent mixtures, including hydrocarbon gases and CO2, are incorporated with the aim of improving its performance.

2008: Bachu, S., Buschkuehle, B.E., Haug, K. and Michael, K. (2008): Subsurface characterization of the Edmonton-area acid-gas injection operations; Energy Resources Conservation Board, ERCB![]() Now AER

Now AER![]() /AGS Special Report 92, 134 p.

/AGS Special Report 92, 134 p.

… From Page 88:

Figure 59 shows the extent of the Acheson original Blairmore T and subsequent St. Albert-Big Lake Ostracod A pools, and of the Strathfield (undefined) gas reservoir in the context of lithofacies changes in the Lower Mannville Basal Quartz and Ellerslie formations. When approval was granted for acid gas injection at Acheson, the regulatory agency required the operator to file annually with EUB and each other operator in the Acheson Blairmore T and St. Albert-Big Lake Ostracod A pools progress reports that “shall include the impact of acid gas injection on the performance of offsetting producing wells”. In March 2004 the operator at Acheson reported that CO2 was detected in 2003 in well 10-22-53-26W4 in the St. Albert-Big Lake Ostracod A pool, located at 3,625 m north from the acid-gas injection well. No H2S has been detected in the produced gas. Since at Acheson the average composition of the acid gas is 87% CO2 and 11% H2S (Table 14), with H2S being denser and more viscous than CO2, it is expected that CO2 would show first at a producing well. In addition, diagenetic processes within the reservoir could have reduced the H2S concentration in the injected acid gas as a result of pyrite precipitation, if an iron source was available. The issue was brought to EUB’s attention and was heading to a hearing, but the operator at Acheson has indicated to the regulatory agency that it has initiated an Appropriate Dispute Resolution process with the operator of the offset producing well to address the issue of CO2 breakthrough, and that this situation “will be addressed pursuant to the terms of the Mediated Settlement Agreement”.![]() To gag the harmed?

To gag the harmed?![]()

This case shows that, after 13 years of injection, CO2 has migrated northward a distance of [nearly 4 km] mostly under the combined drive of injection and production.

The drive into the St. Albert-Big Lake Ostracod A gas pool has increased lately with the large spike in gas production from this pool (Figure 57b). There are five producing wells much closer to the acid-gas injection well (Figure 59) that did not report CO2 breakthrough, but these wells are owned by the same operator that operated until recently the Acheson acid-gas injection site. If acid gas broke through at any of these wells, it is most likely that the operator just stripped the acid gas from the sour reservoir gas and re-injected it, as the produced gas in this area is sour to begin with. Understanding the migration path and fate of the injected acid gas at Acheson requires a separate study that is beyond the scope of this report. …

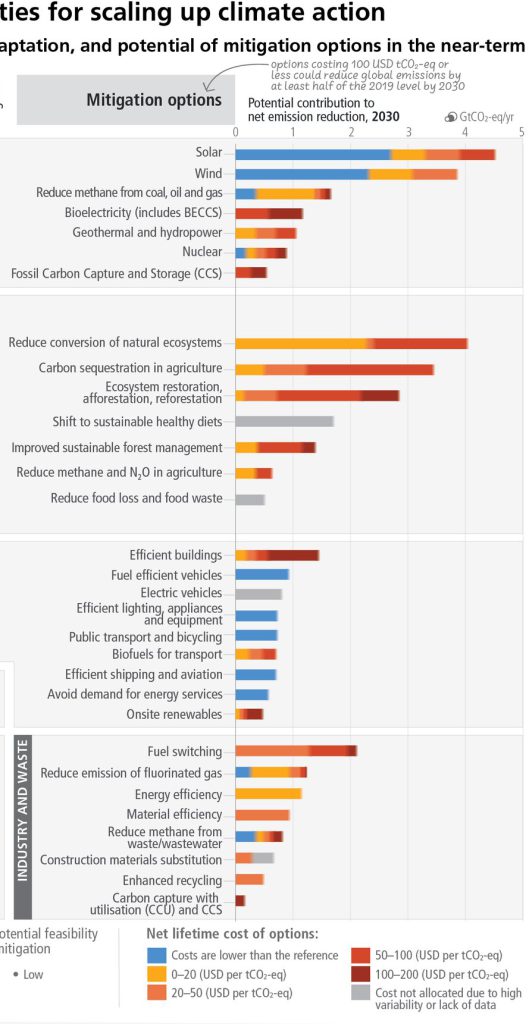

2007: Presentation on above 2006 paper Factors Affecting or Indicating Potential Wellbore Leakage by Watson and Bachu at the Alberta regulator, AER (when it was EUB), no less!

2006 May: The Role of the Upper Geosphere in Mitigating CO2 Surface Releases in Wellbore Leakage Scenarios

2006 June: Possible indicators for CO 2 leakage along wells by Bachu and Watson, 8th International Conference on Greenhouse Gas Control Technologies, Trondheim, Norway

… Storage safety refers to the potential harm to other resources, equity and life that a CO2 leak may entail.

The probability and effects of leakage from CO2 storage sites need assessment by both the operator and regulatory agency during the application and permitting process, during the operational phase and after site abandonment [3].

Any fluid in the subsurface, especially a buoyant one like CO2, will migrate laterally within the injection unit and may leak upwards across formations through faults and fractures and/or defective wells [1, 4].

The potential for CO2 leakage through fractures and faults can be well managed through proper geological characterization and selection of the storage site, and through proper operating procedures.

Managing the potential for CO2 leakage through wells is more difficult.

Exploration and production wells have been drilled, completed and abandoned since the middle of the 19th century, with variable technology and materials, and with no or under variable regulatory regimes. Well materials (cements, steel, elastomers, etc.) will or may degrade over time, particularly in the presence of corrosive agents such as saline formation water and CO2 [5, 6]. Thus, the potential for leakage through existing wells needs to be assessed for site selection and remediation. New wells will also be subjected to the same in-situ conditions as the existing wells.![]() Dr Tony Ingraffea subsequently found new wells to be worse leakers than older ones, which makes sense given the oil and gas industry’s relentless greed, lies, and demanding deregulation which has been consistently granted by our deregulators, notably Alberta’s “No Duty of Care” legally immune bullying shameless AER.

Dr Tony Ingraffea subsequently found new wells to be worse leakers than older ones, which makes sense given the oil and gas industry’s relentless greed, lies, and demanding deregulation which has been consistently granted by our deregulators, notably Alberta’s “No Duty of Care” legally immune bullying shameless AER.![]() …

…