Victory Nickel’s commissioning of Seven Persons Frac Sand Plan underway near Medicine Hat, Rail deliveries of Wisconsin sand concentrate continue to arrive in Alberta Press Release by Victory Nickel Inc., March 19, 2014, Marketwired

Victory Nickel Inc. (“Victory Nickel” or the “Company”) (TSX:NI) today announced that commissioning of the Company’s Seven Persons frac sand plant (the “7P Plant”) near Medicine Hat, Alberta is underway. The 7P Plant has approximately 22,000 tons of dry sand storage capacity, and the inventory build-up of premium-quality midwestern white frac sand is ongoing. In addition, shipments of washed, concentrated sand from the transload facility in Winona, MN continue to arrive at the 7P Plant for processing.

“We have now achieved the milestones of:

500,000 ton-per-year dry frac sand processing facility;

Formation in Wisconsin, USA; and,

said Ken Murdock, CEO of Victory Silica, Victory Nickel’s wholly-owned frac sand-focused subsidiary.

“Our next goal is to build sufficient inventories of 16/30, 20/40, 30/50 and 40/70 frac sand to begin sales into Manitoba, Alberta, BC, Saskatchewan and North Dakota and then build the business from there.”

Frac sand is a proppant used in the oil and gas business as a part of the hydraulic fracturing process – a means of increasing flow to the wellhead. Frac sand must have particular characteristics including achieving certain levels of crush resistance, sphericity and roundness, and it is therefore a relatively rare commodity. Vast quantities of frac sand are consumed, and more is needed all the time, as shale gas and oil plays in Canada and the US rise to prominence.

Victory Silica is a wholly-owned subsidiary of the Company and is charged with a phased plan to establish the Company in the frac sand market. In Phase 1, the Company plans to begin sales in 2014 of premium quality midwestern white frac sand from the 7P Plant in Seven Persons, Alberta near Medicine Hat by shipping partially-processed sand purchased in Wisconsin to the 7P Plant for final processing and distribution. The 7P Plant is well located in an area populated with fracking companies, its potential customers, and is within only a few hours’ trucking distance of major oil or gas play well sites. Phase 2, which includes the construction of a concentrator in Wisconsin, will reduce costs and assure security of sand supply through the control of a frac sand mine in Wisconsin. In Phase 3, Victory Silica has identified a site in Winnipeg, Manitoba, where it plans to build a larger frac sand plant to process and distribute both imported and domestic sands, including sand mined as a co-product of development of a nickel mine at the Company’s 100%-owned Minago project in Manitoba. With margins expected to be in excess of $25 per ton of frac sand sold, the Company should generate sufficient cash flow in Phases 1 and 2 to provide the financial flexibility to expand its activities by developing a second plant as Phase 3 of its growth plan.

Victory Nickel Inc. is a Canadian company with four sulphide nickel deposits containing significant NI 43-101-compliant nickel resources and a significant frac sand resource at its Minago project. Victory Nickel is focused on becoming a mid-tier nickel producer by developing its existing properties, Minago, Mel and Lynn Lake in Manitoba, and Lac Rocher in northwestern Quebec, and by evaluating opportunities to expand its nickel asset base. Through a wholly-owned subsidiary, Victory Silica Ltd., Victory Nickel is establishing a presence in the frac sand market prior to commencing frac sand production and sales from Minago. [Emphasis added]

OSHA calls for silica limit: Proposed silica limit would hurt fracking industry, American Petroleum Institute says by Katherine Lymn, March 18, 2014, Forum News Service

The American Petroleum Institute is one of about 80 organizations and industry groups that will speak in Washington, D.C., at hearings stretching from Tuesday through April 4. The hearings are a part of the rulemaking process before a rule is made final.

OSHA has proposed cutting the limit of exposure to silica to 50 micrograms of respirable crystalline silica per cubic meter of air as averaged over an eight-hour day.

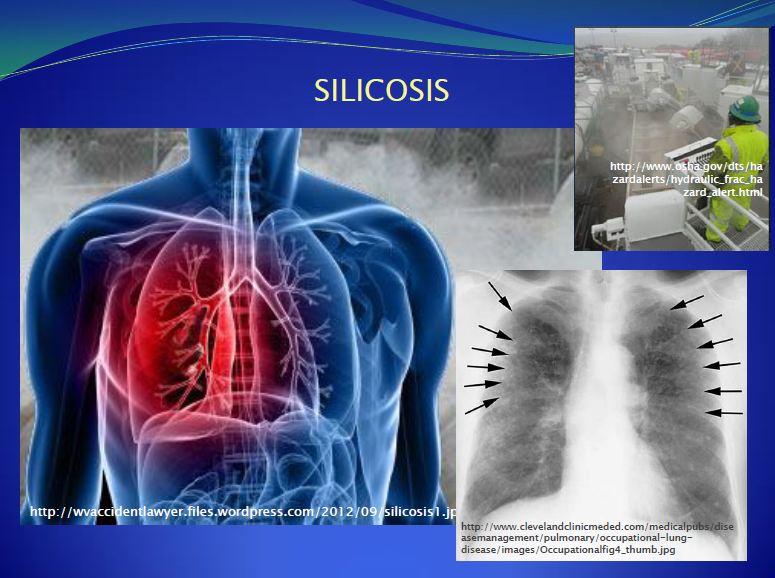

The inhalation of crystalline silica particles can cause silicosis, lung cancer, chronic obstructive pulmonary disease and kidney disease, according to OSHA.

Currently, OSHA enforces 40-year-old permissible exposure limits (PELs) for silica in general industry, construction and shipyards. It estimates the proposed rule, if implemented, would save 700 lives and prevent 1,600 cases of silicosis a year. But industry groups say the rule is not well-researched and that the health effects aren’t sufficiently proven to warrant the new limit.

…

API and IPAA assert the proposed exposure limits are economically infeasible for much of the fracking industry. “In drafting the OSH Act, Congress never intended to protect employees by putting their employers out of business,” they write.

The organizations assert that in a “rushed analysis” of the industry, OSHA underestimated the costs the rule would have for the fracking industry to comply. The costs of following the rule would “create profound detrimental economic consequences as companies — large and small — struggle to implement control technologies that are not commercially available, not effective, cannot be used in conjunction and, in some cases, do not exist,” the organizations wrote.

Exposure to silica is common in construction — airborne silica dust occurs with cutting, sawing, drilling and crushing of concrete, brick and block — and about 1.85 million of the 2.2 million workers exposed to respirable crystalline silica are in the construction trade, OSHA estimates. The rest are exposed through general industry, including about 25,000 in the oil and gas industry. More than 16,000 of those workers are currently exposed above the proposed levels.

…

The U.S. Chamber of Commerce filed its own comments, charging OSHA with building its rule on “a chain of assumptions.” It urged OSHA to withdraw the proposal because employers won’t be able to keep up with the costs not applicable to foreign competitors, Chamber spokeswoman Blair Latoff Holmes said in a statement. … “Of particular concern is that silica (in the form of sand) is a key component in the fracking industry and this proposal would be unworkable in that industry,” Latoff Holmes wrote.

Silica sand is a common proppant in frac fluid, and usually constitutes about 4.5 percent of the mixture, according to API. Frac site workers are exposed to high concentrations of respirable silica dust as they work with fracturing fluids, according to OSHA. Sources of exposure on the frac jobs include dust ejected from thief hatches on sand movers, released from conveyor belts under the movers, dust generated by truck traffic and created as the sand is dropped into or agitated in the blender hopper, OSHA said in its analysis.

One fracking services company with a large presence in North Dakota, Sandbox Logistics, is testifying in support of the rule because it’d be good for business. Its product would bring companies in compliance with the proposed rule, spokesman Cameron Oren said. The sandboxes are a gravity-fed way to transport frac sand that nearly eliminate the dust associated with blowing off sand from a trailer to a storage vessel on-site.

OSHA estimated, based on its research, that 88 percent of frac workers would require more controls to comply with the proposed rule. It recommends compliance through “local exhaust ventilation” systems on thief hatches and conveyors, adding a water misting system and providing operator booths for the most exposed workers. [Emphasis added]

[Refer also to:

Slide above by Larysa Dyrszka MD, September 2013

Slide above by Larysa Dyrszka MD, September 2013