I commend Mr. LeNeveu for his diligence exposing what I see is ample fraud (and many unaddressed valid concerns) regarding the Vivian Sand mining scheme that smells like just another a frac job (con). Mr. LeNeveu has donated an incredible number of hours working on trying to protect drinking water aquifers, environment and families in his community only to watch pathetic lazy health-harm and pollution-enabling by Manitoba authorities and con MLAs. They’re all the same across Caveman Canada and bend over when a corporation, no matter how dubious, sneaky and dishonest, comes along promising jobs (which rarely materialize as promised) and miracles of non harm to residents that are obviously facing risks to their communities, environment, drinking water (some wells already reportedly impacted) and health.![]()

Sio = Sio Silica Corporation

CEC = Manitoba Clean Environment Commission

IR= Information Request

RTC = RTC Solutions, German solar panel manufacturer

CPS = Canadian Premium Sand

MOU = Memorandum of Understanding

The project registry:

https://www.gov.mb.ca/sd/eal/registries/5991wanipigow/index.html

***

Summary by Dennis LeNeveu:

Not only did the CEC deny all my motions, they allowed Sio to inadequately respond to all of my IRs and ignored their own procedures for resolution participant concerns that IRs has not been adequately responded to.

The MB government Trade Minister just signed a memo of understanding with RTC a German company to build a solar panel plant at Vivian before completion of review of CEC approval and licencing. The MOU notice from the MB government has blatant misinformation and states:

Manitoba will assist RCT by supporting applications under various federal

and provincial economic stimulus programs for research and development,

training incentives, manufacturing and green energy equipment investments,

and construction costs.

The RTC and Sio are after grant money from the taxpayer (us).

The MOU states “This new plant will have one of the lowest carbon footprints in the world”

The processing Facility for the sand will use natural gas dryers that requires a new gas line to be built that will also service new natural gas customers. All the extraction equipment is diesel powered. The pump stations for the slurry lines are planned to be electric but this requires new power lines every year when the pump stations are moved. I doubt that the cost of new power lines every year is viable compared to diesel pumping. Even with electric pumping the GHG emissions for the processing facility and extraction make Sio about the 3rd largest emitter in the province. I submitted this calculation but it was ignored.

From what I can find out, pure silicon for solar panels is never sourced from silica sand but from very high quartzite crystalline deposits. The Vivian sand has not been documented to be pure enough for solar panels with commercially available methods.

This plant is not viable. These guys will stick the government (and investor) money in their pockets and run leaving a huge mess behind.

I sent a copy [of my submission] to the Minister and director of the environment more than one week ago asking it be posted on the public registry and of course have received no response. I sent a copy to the secretary of the CEC hearing and got a reply that it cannot be posted on the CEC site because the Hearing is closed. I expect to be stonewalled by all the government agencies.

***

Participant DLN Perspective on the CEC Recommendations for Vivian Sand Extraction Project by Dennis LeNeveu, Aug. 4, 2023

I was one of the Participants (DLN) for the Manitoba Clean Environment Commission (CEC) Hearing of the Vivian Sand Extraction Project. Before the commencement of the Hearing, I submitted a motion and supporting evidence requiring that the proponent, Sio Silica, complete six material actions. The Hearing Participants, Our Line in the Sand and Municipal Silica Sand Advisory Committee submitted motions requiring a delay in the Hearing until Sio Silica rectified material deficiencies identified in the Technical Reviews of the independent experts retained by the Province for the CEC review of the Project. Completion of these motions was required for the CEC to fulfill its mandate to assess the environmental risk of the Project. The CEC denied the motions. The CEC recommendations following the Hearing included some of the essential material actions of my motion including a full scale well-cluster, sand-extraction, field test, further analysis of the stability of the sand-extraction cavity, and a demonstration of the filtration, UV radiation and return to the aquifer of process water. The CEC recommendations verified the need for completion of my motion and the motion of two other Participants to provide essential information to the Hearing.

Evidence from Sio Silica side scan sonar results demonstrated the shale aquitard separating the sandstone and carbonate regional aquifer collapsed into the cavities following sand extraction. The shale aquitard collapse would lead to mixing of aquifer waters which is prohibited by sections 2(e) and 3(1) of the Well Standards Regulation under The Groundwater and Water Well Act and section 6(1) of the Drilling Regulation under The Mines and Minerals Act. The CEC recommended a legal opinion of the collapse of the shale aquitard caused by sand extraction. I submitted numerous formal information requests (IRs) to the Hearing including IRs pertaining to the shale aquitard collapse and the violation of the groundwater and drilling regulations. The CEC did not require Sio Silica to respond adequately to my IRs in the Hearing. The CEC recommendations on shale aquitard collapse and mixing of aquifer waters is not binding. The CEC recommendations verified the need for completion of the IRs to provide essential information to the Hearing.

I submitted a motion that Section 35 Indigenous Consultations must be completed and results available for the Hearing for the CEC to fulfil its mandate to assess the environmental risks identified. The CEC denied the motion.

One of the six material actions of my motion required that Sio Silica complete a comprehensive geochemical sampling and analysis over the entire project area. Sio Silica analyzed only three geochemical samples, two of which were outside the 24 year Project area. The one sand sample within the Project area was taken from a surface stockpile that was exposed to weathering for more than one year. The hydrogeological technical experts retained by the province to review the Project, stated that the sampling of sand from an outdoor stockpile was unacceptable. The evidence in my 14 Day Rule Submission, IRs and oral presentation demonstrated that the Winnipeg formation to be used for the silica sand extraction contains sulphidic geological material including interbedded shale, concretions and oolite.

Canadian Premium Sand (CPS) plans to surface-mine the high purity silica sand from the Winnipeg formation at Wanipigow for a solar glass plant in Selkirk. Acid base accounting and electron microscope pictures from the CPS October 14, 2014, technical report, required to protect investors for publicly traded stock, demonstrate the silica sand is embedded with the sulphidic materials marcasite and pyrite. When brought to the surface and exposed to air and moisture the sulphidic material will cause acid drainage. The province spends millions per year remediating acid drainage from sulphidic mine tailings. Stockpiles of silica sand containing marcasite and pyrite at the Vivian Processing Facility would be a major environmental hazard from acid drainage.

The Natural Resources Canada MEND guidelines for sulphidic geological material require a minimum of 80 samples for disturbed rock exceeding 10 million tonnes. The Sio Silica planned production is 1.36 million tonnes of sand per year for at least 24 years requiring far more than 10 million tonnes of disturbed material. Sio Silica must complete comprehensive sampling throughout the Project area and geochemical analysis of all the material within the Winnipeg Formation including the silica sand, oolite, concretions, and interbedded shale. The acid drainage potential of the silica sand must be determined by acid base accounting tests from samples taken throughout the 24 year Project area. One invalid silica sand sample in the Project area taken near Vivian is egregious and unacceptable considering the major environmental risk of acid drainage.

Dissolved and entrained air in the water returned to the aquifer and air leakage to the aquifer from the air-lift extraction process would mobilize toxic selenium and generate acid from oxidation of the sulphidic materials resulting in release of heavy metals into the aquifers. I submitted IRs for quantification of the air introduced into the aquifers by the Sio Silica processes. Sio Silica did not supply the information requested in the IRs. Without comprehensive geochemical sampling and analysis and quantification of the amount of air introduced into the aquifer by the Sio Silica extraction process, the risks to aquifer contamination from introduced air cannot be assessed.

The CEC simply noted the geochemical concerns and evidence I submitted with no evaluation or follow up.

The province did not hire geochemical experts for the technical review. The province did not provide funding to participants to engage technical experts such as geochemists as is the usual practice for a CEC Hearing. The CEC did not address geochemical issues in their final report. The systemic failure of adequate geochemical technical review and the failure of the CEC to adequately assess the geochemical and acid drainage risks associated with this Project is an egregious failure of the CEC mandate that must the rectified.

The province did not hire independent biological and ecological technical experts to assess the wildlife and habitat disturbance of the Project. Disturbance would include intensive clearing for slurry lines between well clusters, yearly installation of power lines for new pump station locations and newly cleared routes for the main slurry line loop to the Processing Facility. Considering that the total area of mineral claims for the Project is 85,000 hectares the long-term territorial disruption could be extensive. The CEC simply acknowledged statements by the proponent that territorial disturbance would be minor and reversible without adequate evidence and evaluation. The CEC noted resident concerns about noise and night-time light levels but simply repeated statements by Sio Silica that noise and night-time light levels from the Project would be acceptable. The CEC did not request noise and night-time light level measurements for their recommended full scale field tests for a well cluster.

The CEC final report noted, without evaluation, evidence I submitted, that harmful microbes in ambient air and diesel fumes from equipment at the extraction site would be drawn into air compressors for the air-lift sand extraction process. Sio Silica documented in their Environment Act Proposal (EAP) the GHG emissions for an extraction site is about six times the amount for the Processing Facility. Based on the air quality modelling studies for the Processing Facility six times the emissions would result in violations of air quality concentrations for NO2 throughout the extraction site area as documented in my 14 Day Rule Submission. The contaminated compressed air could be introduced into the aquifer during the air- lift sand extraction process. The Groundwater Management Section Water Branch had stated in the Technical Advisory Committee (TAC) Review, October 2021; “The air used to lift the sand-water mixture must be free of lubricants, hydrocarbons or other chemicals that may impact water quality.” The proponent responded that oil free compressors would be used. Oil-free compressors without comprehensive air scrubbing would draw in fumes and microbes in the ambient air. Sio Silica, in response to one of my IRs, stated standard particulate filters, not air scrubbers for removal of microbes and organic fumes would be used for the air compressors during production. The Provincial Approvals Process did not identify and follow up on the inadequate proponent response. The lack of evidence for proponent responses and lack of regulatory follow up to proponent responses to the TAC comments and submitted public comments is endemic in the Provincial Approvals Process. The CEC Hearing did not evaluate the risk of aquifer contamination from the air-lift compressors or require any remedial action for air scrubbing of the compressed air.

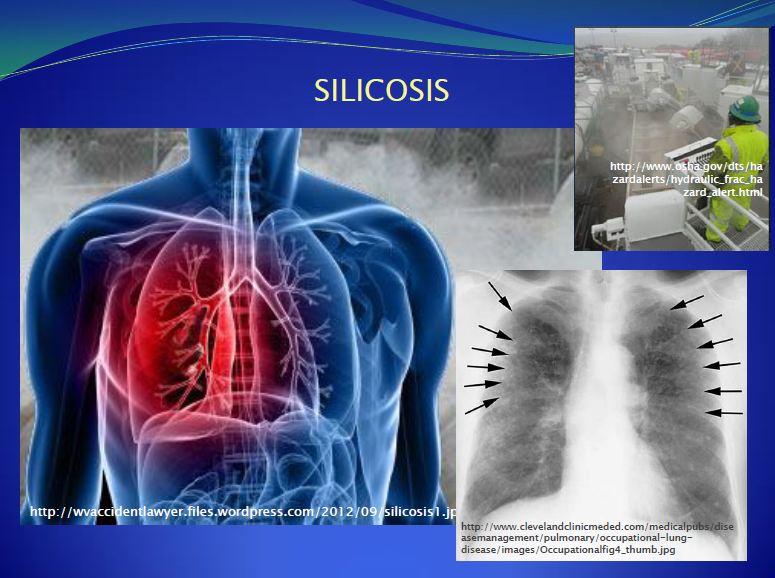

The CEC noted concerns of citizens and presenters about exposure to harmful silica dust from Sio Silica sand piles that were left uncovered during extraction. The CEC stated, “The proponent, in its rebuttal, stated that access gates to the site had been vandalized and showed a photograph of a sand pile that had been covered with tarps.” The CEC ignored the evidence in my 14 Day Rule Submission that the sand piles south of Vivian were uncovered from June 2019 to June 2020. Sio Silica emplaced tarps over the exposed sand piles and an access gate to the extraction site following my formal complaint of June 28, 2020 to Manitoba Workplace Safety and Health that ATV operators and passers by were being exposed to silica dust from the sand piles. In the spring of 2021 another large sand pile was extracted at the quarry southwest of Vivian. Sand was observed blowing from the extracted sand piles toward nearby residences. The quarry pit operators and drillers were not wearing any respiratory protection. It was not until I reported the hazard to Manitoba Workplace Health and Safety on May 10, 2021 that the sand piles were covered. This evidence of exposure to silica dust, reported in my 14 Day Rule Submission, was ignored by the CEC. Sio Silica has not demonstrated that sand piles used at the extraction site during advanced exploration would not be present during production, exposing workers and nearby residents to silica dust that causes silicosis and cancer.

The workers at the Processing Facility and nearby residents could also be exposed to silica dust from the sand stockpiles at the Processing Facility. There is no guarantee of the effectiveness or enforcement of the watering of the stockpiles as proposed by Sio Silica. The licence for the Processing Facility included a definition of the respirable PM 2.5 and PM10 silica dust. The licence has no requirements for measurement of respirable silica dust or for worker protection measures to prevent exposure to respirable silica dust as documented in my 14 Day Rule Submission to the CEC. This is one example of typically inadequate Project licence conditions. Specified licence conditions are usually self-regulated with compliance at the discretion of the Director. The Minster dismissed my appeal of the licence for the Processing Facility with a form letter identical to dismissal letters to others who appealed. The Minister did not address any of the issues raised in the appeals. The Minister simply stated confidence in the approvals process. The blanket dismissal of appeals by the Minister is an example of abuse of the approvals process. The CEC also expressed dissatisfaction with the approvals process particularly concerning the lack of input from the Mines Branch. The CEC did not address the silica dust hazard to workers and the public demonstrating an example of inadequacy in the CEC review process.

The province did not hire independent health and safety experts to evaluate risks such as worker and public exposure to silica dust, diesel fumes, and noise. The health and safety risks of this Project have not been adequately quantified.

The CEC final report noted evidence and modelling I submitted to the Hearing, that the contaminants such as highly toxic acrylamide monomer and selenium would accumulate in the recycled water in the slurry line loop that carries the extracted silica sand to the Processing Facility. Acrylamide is present as a manufacturing residual in the flocculent used for the Processing Facility clarifier tank. References given in a Sio Silica response to one of my IRs verified the presence of acrylamide residual in the polyacrylamide flocculent to be used in the clarifier. Acid would accumulate from oxidation of sulphides in shale, concretion and oolite fragments in the slurry line. Further acrylamide could accumulate in the slurry line from decomposition of polyacrylamide caused by interaction with increasing iron and acid content. Selenium when exposed to air would leach from shale and limestone fragments extracted with the sand in the slurry loop. Shake flasks tests, documented in the Sio Silica EAP, confirmed selenium would leach from the limestone and shale when exposed to air and water. Toxins accumulated in the slurry loop would be released into surface waters upon leakage. The CEC did not assess this environmental risk or recommend remedial actions.

The TAC comment of Sept. 28, 2021 from the Office of Drinking Water stated; “The Office of Drinking Water will not be applying drinking water standards to this project as it is not a regulated water system;” even though the Project could impact drinking water quality. This is an example of narrow jurisdictional issues that have prevented adequate TAC review.

Within the 24 year Project lifetime the slurry lines must cross the Winnipeg aqueduct. Slurry line leakage of acrylamide and other toxins could enter the Winnipeg water supply through known cracks in the aqueduct as documented in my 14 Day Rule Submission to the Hearing. Sio Silica claimed that the aqueduct would not be crossed within the four year time frame of the Project review, therefore the risk to the aqueduct is not to be assessed for the Hearing. The CEC recommended that risks be considered over the entire 24 year project lifetime implying the risk to the aqueduct must be evaluated. The CEC did not assess the risk to the aqueduct.

Stantec, the geotechnical experts retained by Sio Silica, recommended that the carbonate aquifer must have over 15 meters of competent limestone to prevent collapse into the sand extraction cavity. I presented evidence from numerous Sio Silica well information reports obtained from Manitoba Groundwater that the competent limestone thickness east of Highway 302 was less than 15 meters. Sio Silica extraction is scheduled to begin east of Highway 302. Sio Silica responded during the Hearing with data from two wells east of Highway 302 that had total limestone thickness somewhat greater than 15 meters. Sio Silica side scan sonar studies documented three meters of limestone would collapse into the extraction cavity. The top three meters of the carbonate aquifer is comprised of fractured limestone (karst). When this total of six meters of incompetent limestone is subtracted, the competent limestone of the two wells is less than the 15 meter Stantec limit. Thus the data provided by Sio Silica from two wells confirm that no extraction can occur in the area east of Highway 302. The CEC ignored the submitted evidence that silica sand extraction must not occur east of Highway 302.

Sio Silica refused to make the Stantec geotechnical report on the stability of the extraction cavities public based on proprietary information contained in the report. port.![]() It’s easy to redact the trade secrets, if any, and publicly release the report. In my view, it’s suspicious that Sio Silica is refusing to do so, especially as the company isn’t even giving impacted residents or the municipality access to it. Typical of bullying aquifer frac’ers; secrets is the only way they can con “regulators” and gov’ts into granting them approvals, get their lusted after “social licence” to rape the residents, other businesses and community, and let them harm drinking water supplies, and snag billions of public money.

It’s easy to redact the trade secrets, if any, and publicly release the report. In my view, it’s suspicious that Sio Silica is refusing to do so, especially as the company isn’t even giving impacted residents or the municipality access to it. Typical of bullying aquifer frac’ers; secrets is the only way they can con “regulators” and gov’ts into granting them approvals, get their lusted after “social licence” to rape the residents, other businesses and community, and let them harm drinking water supplies, and snag billions of public money.![]() The external technical experts hired for the Hearing were given access to the report. However the Hearing Participants were required to sign a non disclosure agreement (NDA) to obtain access. The NDA specified the Participants would be legally culpable for any disclosure of proprietary information by the Participants or any of their agents including lawyers and technical experts. The independent technical experts found no proprietary information within the report that would warrant public non-disclosure. In any case Sio Silica could have easily redacted commercially sensitive information leaving the essential data on a natural formation in place. The CEC did not require public disclosure of the Stantec report. Nevertheless a truncated version of the Stantec report was published in the proponent response to public comments in January 2022. The truncated version was submitted after the submission of TAC and public comments preventing proper regulatory review by the TAC and the public. The Stantec public version contained data, Table 4, of limestone and overburden thickness and maximum allowed long-term extraction cavity span for these thicknesses. In June of 2022, Sio Silica submitted to the Hearing an extraction plan that specified the cavity span for all well cluster extractions to be 60 meters with 5 extraction wells for each well cluster.

The external technical experts hired for the Hearing were given access to the report. However the Hearing Participants were required to sign a non disclosure agreement (NDA) to obtain access. The NDA specified the Participants would be legally culpable for any disclosure of proprietary information by the Participants or any of their agents including lawyers and technical experts. The independent technical experts found no proprietary information within the report that would warrant public non-disclosure. In any case Sio Silica could have easily redacted commercially sensitive information leaving the essential data on a natural formation in place. The CEC did not require public disclosure of the Stantec report. Nevertheless a truncated version of the Stantec report was published in the proponent response to public comments in January 2022. The truncated version was submitted after the submission of TAC and public comments preventing proper regulatory review by the TAC and the public. The Stantec public version contained data, Table 4, of limestone and overburden thickness and maximum allowed long-term extraction cavity span for these thicknesses. In June of 2022, Sio Silica submitted to the Hearing an extraction plan that specified the cavity span for all well cluster extractions to be 60 meters with 5 extraction wells for each well cluster.

The data from Stantec Table 4 showed the maximum allowed cavity span increased linearly with increasing competent limestone thickness for a given fixed overburden thickness and decreased linearly with overburden thickness (load) for a given fixed limestone thickness. Based on the Table 4 data I presented evidence to the Hearing using limestone thickness and overburden thickness from 44 Sio Silica well information reports that the maximum allowed cavity span over almost the entire project area must be less than 60 meters, varying from about 30 to 50 meters. Following my submitted evidence, on Jan. 24, 2023, four weeks before the commencement of the Hearing, Sio Silica submitted a revised extraction plan. The revised plan specifies well clusters of variable cavity span that depends on the number of wells per cluster varying from one to five. Sio Silica did not specify the method of determination of the number of wells per cluster and the dimension of the cavity spans. Sio Silica stated in response to one of my IRs that the sixty meter cavity span for all well clusters specified in June 2022 is no longer in effect. The revised plan of January 2023 includes extraction east of Highway 302 in violation of the Stantec limit requiring 15 meters of competent limestone. I submitted a motion that the Hearing be delayed until Sio Silica provides detailed information on the method of determination of the number of wells per cluster and the determination of cluster cavity span. Without this information the risk of the carbonate (limestone) aquifer collapse into the extraction cavity cannot be assessed. The CEC denied the motion.

The CEC recommended in their final report that further tests be done to quantify the spatial variability of the limestone stability throughout the project area. Slanted directional drilling is recommended to determine the incidence of vertical fracturing that could affect the limestone stability. Sio Silica used literature values and model back calculation to determine the sand stability parameter values with no direct measurement of sand stability parameter values. The CEC did not address evidence from the Participants and the independent technical advisors that the stability of the sand pillars supporting the extraction cavities was not adequately characterized with respect to special variability and parameter value measurement.

In my 14 Day Rule Submission and my oral presentation I documented evidence from well information reports obtained from the Manitoba Groundwater Section that Sio Silica test production wells 92-2 and 92-3 completed in July 202, southwest of Vivian, had improperly sealed outer steel casings. Improperly sealed annular spaces connect the surface directly to the carbonate aquifer in these two wells. The well information reports showed that well Bru 92-2 had a temporary shale trap seal at the top of the outer casing while well Bru 92-2 had no seal. These wells violate the Manitoba Well Standard Regulation 31(1) that requires a permanent annular fill to a depth of 6 meters below surface to prevent surface-water ingress into the aquifer. Thousands of planned Sio Silica production wells completed in this manner would virtually assure fecal matter, toxic agricultural chemicals and other contaminants would enter the carbonate aquifer by surface water ingress. The CEC did not follow up on this violation of well standard sealing regulations and the serious environmental risk to the aquifer from improper well surface sealing.

Sio Silica documented injection of process water extracted with the sand to the sandstone aquifer in only one well, Bru 92-8. The injection well permit for well Bru 92-8 required continuous measurement of the water pressure in the carbonate aquifer during injection to ensure the injection formation is not over-pressurized. Sio Silica did not measure the water pressure during injection in violation of the injection well permit. Sio Silica claimed that water pressure measurement was not necessary since process water was being returned by gravity feed aided by the pressure drawdown in the sandstone during air-lift sand extraction. Sio Silica claimed that the gravity feed method would not introduce excess pressure. I presented evidence from a model study using an analytical solution, documented in the scientific literature that water return would increase aquifer pressure. The model used both a point source injection of water and a point withdrawal of water directly below to simulate the Sio Silica extraction and water return system. The model demonstrated that significant pressure increase would occur based on the rate of water return regardless of the method of water injection depending only on the rate of injection. This evidence of pressure increase was supported by the Sio Silica patent for the air-lift extraction method that stated that the returned water could induce sufficient pressure, “to facilitate the extraction of the sandstone slurry.” Any increase in pressure would increase the risk of collapse of the carbonate aquifer into the extraction cavity resulting in widespread subsidence at the surface and permanent damage to both the sandstone and carbonate aquifers. The results of my model study showed that returned process water would circulate close to the production tube entering the tube at the bottom providing a barrier to the uptake of sand. The information in the Sio Silica patent also documented this problem. In my 14 Day Rule Submission I documented that the Sio Silica modelling studies using the FEFLOW code did not employ an injection source to represent the return of process water and was therefore faulty. Thus Sio Silica did not provide evidence to support that return of water would not increase aquifer pressure. The CEC ignored the evidence I presented on the risk of water pressure increase and the interference of circulating returned process water with sand uptake. The CEC did not recommend pressure water measurement in their recommended field test of an extraction well cluster.

I submitted evidence to the Hearing that Sio Silica must obtain permission from Manitoba Hydro for extraction near and slurry line crossing of the Pointe du Bois power line and the international power line to Minnesota. In the TAC comments Manitoba Infrastructure (MI) stated that permission must be obtained by Sio Silica for the slurry line crossing of Highway 302. Eventually permission must be obtained by Sio Silica from the City of Winnipeg to cross the Winnipeg aqueduct. CN Rail must agree to connect the Sio Silica rail loop to the CN mainline. This new rail connection according to CN guidelines must include extensive publicly available engineering plans and community consultations. The CEC did not recommend that Sio Silica obtain permissions from Manitoba Hydro, MI, and CN rail for the Hearing or assess the viability of obtaining these permissions. The Sio Silica Project is not viable without these permissions.

The CEC reported the GHG emissions given by Sio Silica for extraction to be 6.8 kt which is 0.03% of the Manitoba emissions in 2019. The CEC ignored the 34 kt GHG emissions from the Processing Facility including emissions from drying of the sand using a new natural gas line as documented in my 14 Day Rule Submission. The indirect GHG from other new users of the natural gas line is ignored. The total of 40.8 kt is not far from the designation of a large final emitter of 50 kt and is therefore not insignificant. The CEC did not recommend electrification of all Sio Silica operations including sand drying to reduce the large GHG footprint of this Project.

According to the Manitoba Mines and Minerals Act advanced exploration means among other conditions; “removal of a bulk sample of at least 500 tonnes of material for testing.” Sio Silica has removed more than 500 tonnes of material for testing since 2018 or earlier. Before commencing an advanced exploration project the proponent must submit and receive approval of a mine closure plan for both the mining and processing. The requirement that the mine closure plan include processing demonstrates that the Project splitting into two independent assessments for extraction and processing was unwarranted. Sio Silica has not complied with this provision of the Act. The responsible provincial Minister ignored a letter from What the Frack Manitoba (WTFM) detailing this violation of the Act. The Manitoba ombudsman did not proceed with my complaint and the WTFM complaint that the Minister did not administer the provisions of the Act regarding an advanced exploration project. The CEC ignored the evidence of this violation of the Mines and Minerals Act that I presented in my 14 Day Rule Submission and IRs. The CEC simply noted in the final report that the closure plan was not available for review. A mine closure plan submitted before commencement of advanced exploration should have quantified risks of subsidence, prohibited mixing of aquifer waters, and other environmental risks that should have prevented this project from ever proceeding. This further demonstrates a systemic failure in the Manitoba Project Approvals Process.

The CEC recommended that, “a cumulative effects assessment for the full 24-year life of the project be carried out and its impact be considered in light of other existing and foreseeable projects in the area.” The mine closure plan must include cumulative effects. The cumulative effects assessment requires a joint assessment of the Processing Facility, sand extraction, rail loop and other projects such as sand and gravel extractions in the area.

I submitted extensive IRs to the CEC Hearing that the proponent either answered inadequately or deemed to be irrelevant. I submitted a motion requesting the CEC implement the documented procedures for resolution of Participant-perceived inadequate responses to IRs. The CEC denied the motion yet recommended in their final report that the proponent provide much of the information I had formally requested in my IRs. The CEC recommendations need not be followed. The CEC could have delayed the Hearing until Sio Silica provided the information for my IRs and motions thereby ensuring this essential information was provided and assessed by the Hearing. By failing to require Sio Silica to provide the essential information for the Hearing the CEC has failed to fulfil its mandate.

The CEC final report stated that “The proponent states that the sand to be mined is among the best available sources of high-purity sand in the world, with 99.85 per cent purity in its raw form and processed purity greater than 99.9 per cent.” The CEC reported this data and information without documented evidence on the source of the data, the variability of the raw-sand purity over the Project area and the methods required for obtaining the purity required for solar panels and other high purity applications. Sio Silica submitted to the Hearing only one heavily redacted laboratory report of the content of purified silica sand. Sio Silica did not disclose the location of the sand sample and the purification methods.

The high purity silica sand in the Winnipeg Formation, laid down in a shallow sea in the middle of the Laurentia continent over 400 million year ago, covers an enormous area over Saskatchewan, Manitoba, North Dakota, Minnesota and Wisconsin. This high purity sand has been extracted where it sub-crops near the surface in Minnesota, Wisconsin, Black Island Manitoba and Hanson Lake Saskatchewan. The province has issued a licence for the extraction of high purity silica sand at Minago Lake, Manitoba. Extraction at Minago Lake would not endanger a large regional aquifer as would extraction near Vivian. The high purity silica sand is by no means unique to Vivian. There are much less environmentally risky alternative sources of high purity silica sand.

The CPS October 14, 2021, technical report for the Wanipigow Silica Sand Project states, the required silica sand purity for solar glass and other high purity applications is of the order of 100 parts per million of impurity or less. The stated purity of Vivian sand after treatment of 99.9 percent quoted in the CEC final report corresponds to 1000 parts per million of impurity. The 2021 CPS technical report states that acid washing is required to achieve the purity required for solar glass. The CPS acid wash was demonstrated only with small batch tests. The CPS technical report states that bulk tests (e.g. 500 kg) with actual raw materials are required to demonstrate commercial viability. Only a small portion of the total Wanipigow quarry area of CPS is of sufficient purity for solar glass. Sio Silica has not provided data on the portion of their mineral claims that would be suitable for solar panels or other high purity applications. I documented all this evidence in my 14 Day Rule Submission to the CEC and in my oral presentation. The evidence I submitted on the uncertainty in obtaining high purity was not evaluated by the CEC. The CEC is negligent in not requesting the sampling data and the beneficiation procedures to support the very foundation of this Project for high purity silica sand applications.

An over 500 page fully referenced scientific report submitted to the Hearing by Dr. E. Pip independently corroborates the evidence in my motions, IRs,14 Day Rule Submission and oral presentation. The CEC did not consider the evidence submitted by Dr. E. Pip.

The CEC did not adequately fulfill its mandate to assess the environmental risks embodied in the motions, IRs and oral presentations submitted during the Hearing. Instead the CEC recommends another ill-defined un-established review process to complete its unfilled mandate.

In my opening remarks to the Hearing I asserted that the direct proponent funding of the EAP was fundamentally flawed. The hired consultants necessarily document information only beneficial to the proponent otherwise they would be terminated. The EAP must be expanded to a full Environmental Impact Statement (EIS) prepared through an independent agency funded by the proponent. Initially a CEC Hearing was not proposed for the Project. A Licence would have been issued subsequent to the biased EAP, rife with missing information, and subsequent to the inadequate responses to the TAC and public comments. The CEC Hearing was scheduled only after extensive pressure from the local RMs and concerned citizens. The decision for a CEC Hearing should not be solely in the hands of the Minister who would be subject to political pressure. The independent agency administering the EAP should recommend the requirement for a CEC Hearing.

The provincial environment minister has committed only to a review of the CEC recommendations by provincial government experts and to consultations with Indigenous Groups. The CEC identified that the original TAC review process before the Hearing was flawed. For example the Mines Branch was missing in action. The Mines Branch did not participate in the TAC review or in the Hearing. The Mines Branch did not enforce the Drilling Regulations on movement of fluids between aquifers and the requirement of Mines Minerals Act for filing of a mine closure plan before commencement of advanced exploration. TAC reviews by other government departments were piecemeal, restricted by departmental jurisdiction and uncoordinated. Proponent responses to the TAC and public comments were not followed up and evaluated in the provincial approvals process prior to the Hearing. Another review by provincial experts without a prior requirement of completion of the actions in the CEC recommendations is unacceptable.

The Minister must require that Sio Silica complete all actions of the CEC recommendations. The Minister must reconvene the CEC with a new Panel to assess the completion of these required actions. The Minister must not implement some other, ill-defined review process, which would not necessarily include public input, full transparency, and independent expert review embodied in the already established CEC procedures. The Minister must withdraw the licence for the Vivian Processing Facility and require a revised EAP for a single Project covering both the Processing Facility and the Extraction and a cumulative effects assessment.

The failure of the province to engage adequate independent technical experts and to provide funds to Participants to engage independent technical experts has prevented an adequate CEC review. The Province must hire geochemical experts with extensive experience in underground acid generation and migration of toxins for the reconvening of the CEC. The province must hire independent biological and ecological technical experts to assess the wildlife and habitat disturbance of the Project for the second round of the CEC Hearing. The province must hire independent health and safety experts to evaluate noise, silica dust, diesel fume and other industrial Project risks to workers and the public. The Province must provide the CEC Participants with adequate funding to engage independent technical experts in the second round.

For the second round of the CEC Hearing the Minister and the CEC must also require Sio Silica to:

- Obtain permission to cross the two Manitoba Hydro power lines, Highway 302 and connect the Processing Facility rail loop to the CN mainline;

- Submit a comprehensive mine closure plan for both extraction and processing;

- Submit a detailed revised silica sand extraction plan with no extraction east of Highway 302;

- Fully document the methods to determine the number of wells per cluster and the maximum allowed long term cavity span for each well cluster in a revised extraction plan that includes the year of operation;

- Fully document the field methods used to determine the cavity span during extraction;

- Fully document the methods required to obtain the silica sand purity required for solar panels and other high purity applications;

- Fully document the waste streams and required disposal for the silica sand purification methods;

- Submit results from a near field hydrogeological model that includes both sand extraction simultaneous process water re-injection varying parameter values to reflect sand withdrawal and aquitard and limestone collapse into the extraction cavity. The model must include the long term mixing of aquifer waters within the extraction cavity due to the regional hydraulic gradient and nearby water well induced gradients;

- Submit a comprehensive cumulative effects assessment including the extraction, Processing Facility, rail loop, and issues from Indigenous Consultations for the 24 year Project period and;

Require electrification of extraction operations and sand drying to reduce GHG emissions.

For the second round the Minister and the CEC must require an independent technical entity funded by Sio Silica to:

- Measure and report the ambient and the compressed air quality and pressure in full scale extraction field test with seven extraction rigs operating simultaneously together with all related diesel equipment including vehicles, vacuum trucks, and generators for nightlights;

- Measure the air quality including silica dust in a full scale extraction field test that includes the transfer of extracted sand to slurry lines;

- Model and report the air quality plumes from an extraction site including all potential generators of air contaminants including silica dust;

- Measure and report the water pressure in the carbonate aquifer adjacent to the return of process water and in sandstone aquifer in the extraction cavity during the well cluster field test;

- Measure and report the noise levels and night-time light pollution levels in a full scale extraction field test with seven extraction rigs operating simultaneously and all related diesel equipment including vehicles, vacuum trucks, night light generators;

- Assess the risk to the Winnipeg aqueduct including input from City of Winnipeg experts;

- Collect in excess of 80 samples of from each of the Winnipeg Formation, the shale aquitard, and the Red River carbonate through the 24 year Project area and geochemically analyze the samples including acid base accounting tests, shake flask tests, leaching tests, heavy metal content and silica sand purity. Air-lift must not be used in the sampling or any other method that would expose the samples to oxidation of sulphide during extraction;

- Measure and report over the entire project area, the sand stability parameter values from numerous samples taken in a non-disruptive manner such as sonic drilling;

- Oversee a comprehensive, Sio Silica funded, three-dimensional geotechnical stability analysis of the extraction cavities using the variability in the field data from slant drilling and new limestone and sand stability parameter measurements over the entire Project to quantify the uncertainty;

- Measure and report the dissolved oxygen, gaseous entrained air content, total organic, benzene, microbe, dissolved heavy metal, water quality, turbidity and pH in the water of both aquifers before and after a full-scale field sand extraction test;

- Measure and report the dissolved oxygen, gaseous entrained air content, total organic, benzene, dissolved heavy metal, iron, manganese, pH, hardness, turbidity, total dissolved solids, microbial content, and total suspended solids of the process water to be returned to the aquifer before and after chitosan filtration and UV radiation;

- Evaluate the well construction and well sealing methods in the well-cluster field test including the outer annulus as documented in wells Bru 92-2 and Bru 92-3;

- Independently verify the methods required to purify the silica sand (beneficiation) and to environmentally safely dispose of the purification waste streams.

The CEC, the newly hired technical experts, and existing technical experts must assess the completion of CEC and above recommended actions. The CEC must assess all the measurements and the reports from the independent entities and assess information from the Participants, Participant experts and the public in the second round of the Hearing.

Before signing a development agreement with Sio Silica the RM of Springfield must ensure the above actions are carried out as a precondition.

Should the above actions not be implemented a Judicial Review of the Approvals Process for the Processing Facility and the Extraction, the CEC Hearing, and the subsequent Ministerial Project Review, must be carried out before the issuance of a Project Licence. All the inadequacies documented above must be considered in the Judicial Review.

The Manitoba environmental approvals process must be fundamentally changed as follows:

- An EIS must be prepared through an independently proponent funded third party agency;

- The third party agency must recommend the classification of the Project as 1,2 or 3 and recommend the requirement for a CEC Hearing;

- The government experts (TAC) reviewing the EIS must cooperate and not be restricted by their jurisdictional constraints;

- The government TAC experts must review and assess public comments;

- The third part experts engaged by the independent agency must prepare the proponent responses to TAC and public comments;

- All proponent responses to public and TAC comments prepared by the independent agency must be backed up with verifiable evidence;

- Cumulative Effects must be included in the EIS;

- Section 35 Indigenous Consultation and the publicly available reports must be completed before TAC and public comments and a CEC Hearing;

- Proponent responses, public comments must be thoroughly evaluated by the TAC and the public and proceed through as many rounds as required to resolve outstanding issues;

- The recommendations of the 2015 Manitoba Law Reform Commission review of the Manitoba environmental assessment and licensing regime must be implemented;

- The independent agency charged with the preparation of the EIS must recommend the requirement for a CEC Hearing; and

- The independent agency must specify Project licence conditions subject to approval by the Minister.

Dennis LeNeveu, M.Sc., Participant DLN in Vivian Sand CEC Hearing

***

Manitoba Government, RCT Solutions Sign Memorandum of Understanding to Advance $3-Billion Solar Manufacturing Proposal News Release by Manitoba gov’t, July 26, 2023

Project Would Create 8,000 ![]() This blatant greed-inducing propaganda made me laugh out loud. Our gov’ts can’t come up with a creative thought or lie to bamboozle the citizenry into swallowing their invasive harmful projects that make profit for a few, intentionally leaving the mess and contaminated drinking water for us to endure.

This blatant greed-inducing propaganda made me laugh out loud. Our gov’ts can’t come up with a creative thought or lie to bamboozle the citizenry into swallowing their invasive harmful projects that make profit for a few, intentionally leaving the mess and contaminated drinking water for us to endure.![]() Jobs, Give Manitoba Major Export Advantage over International Competitors: Wharton

Jobs, Give Manitoba Major Export Advantage over International Competitors: Wharton

To power the growth of Manitoba’s low-carbon economy and set a strategic course toward domestic renewable energy manufacturing,![]() In my view, if the gov’t were telling the truth, they’d explore their plans with Canadian companies, not one in Europe

In my view, if the gov’t were telling the truth, they’d explore their plans with Canadian companies, not one in Europe![]() the Manitoba government has signed a memorandum of understanding with German solar technology provider and manufacturer RCT Solutions to explore the construction of a state-of-the-art production facility within the province, Economic Development, Investment and Trade Minister Jeff Wharton announced today.

the Manitoba government has signed a memorandum of understanding with German solar technology provider and manufacturer RCT Solutions to explore the construction of a state-of-the-art production facility within the province, Economic Development, Investment and Trade Minister Jeff Wharton announced today.

“This plant would be the first of its kind in the world with a fully integrated manufacturing process when it is completed,”![]() Why not give that opportunity and the expert design and planning jobs to Canadians?

Why not give that opportunity and the expert design and planning jobs to Canadians?![]() said Wharton. “Our government has worked tirelessly to create a business environment in which a global company like RCT Solutions can thrive and grow, and we’re pleased to begin the process of welcoming them to our province.”

said Wharton. “Our government has worked tirelessly to create a business environment in which a global company like RCT Solutions can thrive and grow, and we’re pleased to begin the process of welcoming them to our province.”

RCT Solutions is planning to develop the cleanest advanced manufacturing hub in the world in Manitoba, the minister said, adding that RCT and its partners are exploring options to invest $3 billion into the new facility, with the potential to create 8,000 permanent, full-time jobs for Manitobans.

The project is expected to be an innovative and fully integrated solar panel manufacturing plant to service the North American market and create a major export advantage for Manitoba, the minister added. Market demand for solar panels in the United States is forecast to reach 45 gigawatts of annual sales by 2027. The RCT Solutions manufacturing plant will be the largest and first of its kind, with a total annual production capacity of 10 gigawatts, or 10,000 megawatts, of solar panel power when fully operational.

“Supplying a significant portion of North America with solar panels is an incredible opportunity for Manitoba,” said Wharton. “This new plant will have one of the lowest carbon footprints in the world![]() I do not believe that will transpire

I do not believe that will transpire![]() , and the solar panels manufactured and exported will significantly increase Manitoba’s gross domestic product (GDP) and the province’s bottom line.”

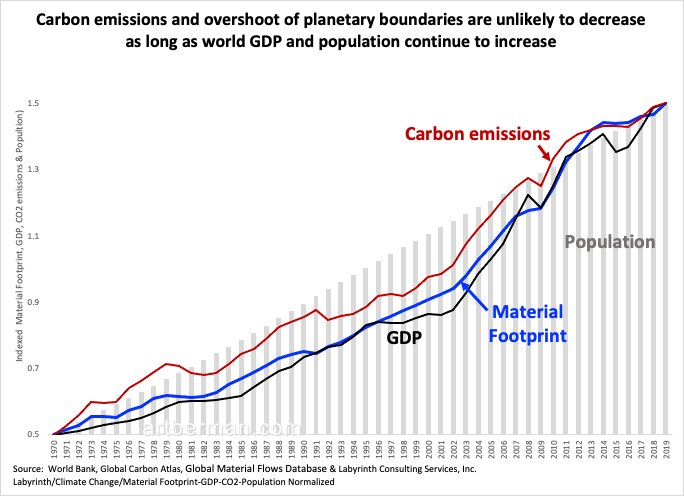

, and the solar panels manufactured and exported will significantly increase Manitoba’s gross domestic product (GDP) and the province’s bottom line.”![]() Increasing GDP feeds greed and escalates destruction of earth’s livability via human caused pollution.

Increasing GDP feeds greed and escalates destruction of earth’s livability via human caused pollution.

Who pays to haul safe alternate drinking water and clean up after the rich have raped the communities impacted and run, as always happens in Canada?![]()

Under the memorandum of understanding, RCT Solutions will undertake to complete a project design, undergo a site selection process, and present a development plan for the facility to the Manitoba government.

Manitoba will assist RCT by supporting applications under various federal and provincial economic stimulus programs for research and development, training incentives, manufacturing and green energy equipment investments, and construction costs.![]() How many millions of dollars will the citizenry cough up – not for the project or the magical thousands of jobs – for planning the project, thinking about it, designing it, only for Sio Silica to later say, “Ooopsie. We’re after frac sand afterall!”?

How many millions of dollars will the citizenry cough up – not for the project or the magical thousands of jobs – for planning the project, thinking about it, designing it, only for Sio Silica to later say, “Ooopsie. We’re after frac sand afterall!”?![]()

“Today marks a transformative milestone as we embark on a journey to revolutionize the solar energy landscape,’’ said Peter Fath, founder and CEO, RCT Solutions. ‘’With our cutting-edge solar panel manufacturing facility, we are poised to produce a staggering two million solar panels annually, right here on domestic soil. This is not just about numbers; it is about powering a brighter, greener future for our planet right here in North America.![]() But you won’t be alive to see it, after the deadly silica sand invades your lungs.

But you won’t be alive to see it, after the deadly silica sand invades your lungs.![]() By harnessing the potential of clean energy

By harnessing the potential of clean energy![]() If Sio Silica and the MB gov’t were sure of the sand to be mined will be used for solar panels, they’d say “by harnessing clean energy” not the potential of it

If Sio Silica and the MB gov’t were sure of the sand to be mined will be used for solar panels, they’d say “by harnessing clean energy” not the potential of it![]() , we are proud to announce that our factory will single-handedly

, we are proud to announce that our factory will single-handedly ![]() Such drama!

Such drama!![]() reduce carbon emissions by a remarkable 14 million tons every year.

reduce carbon emissions by a remarkable 14 million tons every year.![]() Can’t fool me. I’ve lived frac’d now for 20 years. I can smell a frac con and its associated lies a million miles away.

Can’t fool me. I’ve lived frac’d now for 20 years. I can smell a frac con and its associated lies a million miles away.![]() It is a testament to our unwavering dedication to combat climate change and leaving a positive legacy for generations to come.”

It is a testament to our unwavering dedication to combat climate change and leaving a positive legacy for generations to come.”

Currently, global solar panel manufacturing is dominated by Chinese manufacturers![]() Typical con gov’t, gotta enrage their base with racism and rile up to divide and conquer the community

Typical con gov’t, gotta enrage their base with racism and rile up to divide and conquer the community![]() , with world market share in critical component manufacturing ranging from 78 to 97 per cent, the minister noted. The Manitoba facility would significantly reduce North American dependence on imported product.

, with world market share in critical component manufacturing ranging from 78 to 97 per cent, the minister noted. The Manitoba facility would significantly reduce North American dependence on imported product.![]() Always the same scams. Always. Zero creativity and no respect for the citizens forced to pay for being conned, yet again.

Always the same scams. Always. Zero creativity and no respect for the citizens forced to pay for being conned, yet again.![]()

Manitoba has a number of economic advantages for attracting major businesses like RCT Solutions to the province, said Wharton, including an abundance of high-quality critical minerals such as copper, cadmium, and quartz needed for the worldwide solar industry. Manitoba’s reliable and renewable hydroelectricity, highly-specialized workforce, and geographic location at the centre of North America all make the province well-positioned for exciting new manufacturing opportunities, particularly in the critical minerals sector, Wharton added.

The RCT Solutions manufacturing project aligns with the Opportunities for Economic Growth ![]() Pfffft, I think it’s just about more money for the rich stolen out of taxpayer pockets, and lots of huffy unimaginative grossly embellished hot air.

Pfffft, I think it’s just about more money for the rich stolen out of taxpayer pockets, and lots of huffy unimaginative grossly embellished hot air.![]() Action Plan and the Manitoba Critical Minerals Strategy, comprehensive sets of tangible, focused and strategic actions that the Manitoba government is advancing in partnership with stakeholders and the private sector to create a stronger economic future for Manitobans, Wharton said.

Action Plan and the Manitoba Critical Minerals Strategy, comprehensive sets of tangible, focused and strategic actions that the Manitoba government is advancing in partnership with stakeholders and the private sector to create a stronger economic future for Manitobans, Wharton said.

In 2021, the advanced manufacturing sector contributed $6.2 billion to the province’s total GDP and employed over 35,000 Manitobans.

To view the Opportunities for Economic Growth Action Plan, visit Manitoba.ca/economicgrowth.

To view the Manitoba Critical Minerals Strategy, visit www.gov.mb.ca/iem/explore/files/criticalmineralsstrategy.pdf.

For more information on Manitoba’s competitive business advantages, visit Manitoba.ca/InvestMB.

30 –

For more information:

Public information, contact Manitoba Government Inquiry: 1-866-626-4862 or 204-945-3744.

Media requests for general information, contact Communications and Engagement: email hidden; JavaScript is required.

Media requests for ministerial comment, contact Communications and Stakeholder Relations: 204-451-7109.***

Additional comments by Dennis LeNeveu:

We are an evil failed species but not all are like that. I try to limit my association to a very few good people like you. Thank-you for listening to me and being supportive. Your support sustains me.

I have appealed three other licences. The appeals are ignored and dismissed without meaningful response. Several appealed the licence for the Vivian Sand Processing Plant. My appeal and all the others received the identical form letter from the minister simply stating that we should have faith in the approvals process.![]() Pffft! That minister is out of line. No one in Canada ought to have any faith in any politician, minister or not, federal or provincial (or judge for that matter), when it comes to fake or real energy projects, or incredibly dubious mining projects like Sio Silica’s.

Pffft! That minister is out of line. No one in Canada ought to have any faith in any politician, minister or not, federal or provincial (or judge for that matter), when it comes to fake or real energy projects, or incredibly dubious mining projects like Sio Silica’s.![]()

There are four different projects. It is hard to keep track of the goings on in each project.

The window for appeal for the licence alteration for the Wanipigow Sand Project was very small. I had to rush to meet it. The project already had a licence for frac sand but they pivoted to solar glass. ![]() Tricky. Dirty Buggers.

Tricky. Dirty Buggers.![]() There is an approved licence for a solar glass plant in Selkirk, my home town. I appealed that licence. I have received no response for that licence appeal.

There is an approved licence for a solar glass plant in Selkirk, my home town. I appealed that licence. I have received no response for that licence appeal.

The source of the sand for the Selkirk solar glass plant is Wanipigow. The 2014 NI43-101 report to protect investors documents an acid base accounting test that shows the sand is acid generating. This likely makes the entire operation unfeasible. I have been documenting this report since 2108 in my public comments and licence appeals. Canadian Premium Sand (CPS) has officially denied that the sand is acid generating in response to my original public comments for this project.

The latest alteration report admits that a sand sample was potentially acid generating and the shale covering much of the area but not the glass sand area is acid generating. The alteration report has ignored the results from the 2014 NI 43-101 technical report even going as far as saying no other data exists.

Press announcements say Solar glass manufacturer CPS has contracted HFT as its EPC contractor to conduct pre-construction design and engineering for its new production facility.

There are many announcements of MOUs with other companies and funding sources in this post https://cpsglass.com/news/:

CPS Announces Close of Upsized Financings of $9.6 million

August 31, 2022

CPS is pleased to announce that it has closed its previously announced brokered and concurrent non-brokered private placements, pursuant to which the Company issued an aggregate of 32,100,000 units of the Company at a price of $0.30 per Unit for gross proceeds to the Company of $9,630,000.

As far as I can see this is smoke and mirrors. They have not actually sold the shares and received the capital as far as I can tell.![]() Smells like a frac-hustling rat to me, con investors and gov’ts for big bucks, make an enormous harmful mess, run for the bankruptcy hills via a frac-friendly judge to evade clean and pocket big money.

Smells like a frac-hustling rat to me, con investors and gov’ts for big bucks, make an enormous harmful mess, run for the bankruptcy hills via a frac-friendly judge to evade clean and pocket big money.![]()

This post says CPS has a net cash balance over debt.

2023 04 16: Is Canadian Premium Sand (CVE:CPS) Weighed On By Its Debt Load?

As you can see below, at the end of December 2022, Canadian Premium Sand had CA$2.69m of debt, up from CA$2.34m a year ago. However, its balance sheet shows it holds CA$5.69m in cash, so it actually has CA$3.00m net cash.

As far as I can tell the company has no revenue so the cash must come from investors.

Below is a graph of its revenue:

Note comment below graph: “CPS is currently unprofitable.”

The Company has secured firm commercial off-take agreements with three North American solar panel manufacturers including, Hanwha Solutions Corporation (Hanwha), Heliene Inc. (Heliene) and Meyer Burger Technology AG (Meyer Burger), for a combined total of 62% of planned output capacity and an average renewable contract term of over 4 years. These agreements include options to increase firm off-take volumes by an additional 15% of planned output capacity to a combined total of 77%, subject to mutual agreement.

This looks like a massive fraud to me.![]() To me too.

To me too.![]() The City of Selkirk and the MB approvals and government see only the promise of 800 jobs. What is more important is that the deposit is acid generating and should not be mined. There are other sources of silica for a glass plant that do not have this liability. What this appears to me is that CPS has acquired and invested in a worthless deposit and has scammed everyone into this glass plant scheme so as not to lose all its investment in this worthless deposit.

The City of Selkirk and the MB approvals and government see only the promise of 800 jobs. What is more important is that the deposit is acid generating and should not be mined. There are other sources of silica for a glass plant that do not have this liability. What this appears to me is that CPS has acquired and invested in a worthless deposit and has scammed everyone into this glass plant scheme so as not to lose all its investment in this worthless deposit.

The deposit is very close to Wanipigow treaty lands. An Anishinaabe group from Wanipigow has set up Camp Morning Star (CMS), a tepee, next to the entrance to the site. CMS intends to block this Project.![]() Good!

Good!![]() The tepee has been burned down twice.

The tepee has been burned down twice.![]() Horrific.

Horrific.![]() We might have class action and RCMP involved here at some point. Section 35 Indigenous consultation has not been held. CPS claims there is no effect on the treaty land even though they will have silica sand stockpiles overlooking treaty lands and likely acid drainage onto treaty lands. CPS completed a revised Air Quality study that shows safe levels of silica dust from the operation. The documentation of the input parameters is insufficient for me to verify the validity of this modelling. This is CPS modelling. The modeller was hired to give a favourable outcome. It is easy to twiddle input values to a model to achieve the desired outcome.

We might have class action and RCMP involved here at some point. Section 35 Indigenous consultation has not been held. CPS claims there is no effect on the treaty land even though they will have silica sand stockpiles overlooking treaty lands and likely acid drainage onto treaty lands. CPS completed a revised Air Quality study that shows safe levels of silica dust from the operation. The documentation of the input parameters is insufficient for me to verify the validity of this modelling. This is CPS modelling. The modeller was hired to give a favourable outcome. It is easy to twiddle input values to a model to achieve the desired outcome.![]() Of course it is, industry scammers do it regularly, with gov’ts and regulators engaging in fraud giving assistance.

Of course it is, industry scammers do it regularly, with gov’ts and regulators engaging in fraud giving assistance.![]()

The level of manipulation at all levels in this project is staggering.

![]()

For more information, background and reports, refer to:

Vivian Silica Sands, Manitoba Canada

CanWhite Sands out of Calgary changed its name to Sio Silica Corp. To befuddle the many citizens opposed?

A few photos of Sio Silica’s Modus Operandi at Vivian (when it was CanWhite Sands); silica dust can be deadly to breath in for workers and residents living next door:

Would you trust such a company and its operations?

In my view, corporate name changes fix little.

Slide above by Dr. Larysa Dyrszka