Public Advisor on Fracking Filed Fracking Patent by Andrew Nikiforuk, July 17, 2014, The Tyee.ca

Maurice Dusseault, a prominent petroleum engineer now advising the Nova Scotia Hydraulic Fracturing review panel and the New Brunswick Energy Institute (NBEI) on related energy issues, filed for a patent on the controversial technology in 2011.

But Margo MacGregor, program administrator for the Nova Scotia review, says that’s not a problem because all panel members were required to sign off on a code of conduct and “all relevant industry, government and NGO links will be made explicit in our final report.”

Last year the government of Nova Scotia appointed Dusseault and nine other experts to a panel to explore “the social, economic, environmental, and health implications of hydraulic fracturing practices.”

Chair David Wheeler promised that the Nova Scotia study will be “rigorously independent and evidence led.”

Maurice Dusseault, one of North America’s most accomplished petroleum researchers and professor of earth sciences at the University of Waterloo, submitted a patent three years ago to fracture shale rock with a radically different process using less pressure and fluid over longer periods of time.

The patent notes that the current process of “frac-and-pack,” the subject of intense controversy across North America due to water concerns and large science gaps; injects water, chemicals and sand into formations at a rate of 15 to 20 barrels per minute.

This high-pressure fluid injection cracks open hydrocarbon-bearing rocks on a massive scale and then releases small amounts of oil or gas. (The shallow fracturing of coal bed seams in Colorado, New Mexico and Alberta has resulted in extensive methane contamination of groundwater.)

“However,” adds Dusseault’s patent, “this is often accompanied by serious environmental consequences such as a large surface ‘footprint’ for the necessary supplies and equipment as well as relatively high costs.”

In contrast Dusseault’s invention would fracture a rock formation over several weeks at lower pressures “using process control techniques during injection to: optimize formation injectivity, maximize formation access, and maintain fracture containment with the formation.”

Dusseault ‘beyond reproach’ says NBEI chair

Dusseault recently served on a federal panel that examined hydraulic fracturing. The Council of Canadian Academies report recommended a go-slow approach due to lack of baseline data on many critical issues as well as the total absence of proper groundwater monitoring in any province.

Chair John Cherry said that Dusseault offered invaluable, professional and critical advice to the panel.

The professor, who has authored hundreds of scientific articles on everything from leaky wellbores to cap rock integrity in the oilsands, also wrote a paper for the Nova Scotia Hydraulic Fracturing panel.

It concluded that the risks of leaky wellbores “are not great as shown by years of experience” and that the environmental consequences of seepage of natural gas in aquifers “are not catastrophic, albeit undesirable.”

Yet in a separate and much more comprehensive paper on the growing and highly significant industry liability, Dusseault used much stronger language.

Together with hydrologist and co-author Richard Jackson, the professor concluded that natural gas seeping from Canada’s 500,000 wellbores represent “a threat to environment and public safety” due to groundwater contamination, greenhouse gas emissions and explosion risks wherever methane collects in unvented buildings and spaces. He also called for major reforms.

Dusseault also sits on the board of the NBEI, another group that has looked at the economic promise and environmental costs of shale gas development in Atlantic Canada.

David Besner, current NBEI chair, told The Tyee that Dusseault’s ethics “are beyond reproach” and this international expertise makes him an invaluable asset for the debate.

“Dr. Dusseault has certainly made a full declaration of his background and interests to my predecessor, the first chair of the NBEI prior to his appointment,” added Besner.

The first chair of the NBEI, Louis LaPierre, resigned last year after the professor, a strong advocate of hydraulic fracturing, admitted that he had misrepresented his academic credentials.

LaPierre claimed in his biography that he held a doctorate in ecology from the University of Maine, but a CBC investigation found that LaPierre received a doctorate in education from Walden University in Minnesota instead.

LaPierre opposed a moratorium on fracking and wrote a controversial study suggesting that the citizens of New Brunswick just needed more information on the industry to overcome their fears.

Fracking ‘ill understood’ by public: Dusseault

Rural communities across Eastern Canada have mobilized to oppose the technology due to the industry’s problematic mining legacy: fragmented farmlands, property devaluation, groundwater contamination, damaged public roads, waste water production, air pollution, earthquakes and regulatory neglect.

Dusseault’s research on geomechanics, heavy oil and leaky wellbores often criticizes industry practices and has been regularly cited by The Tyee.

Dusseault replied to a Tyee query about his patent disclosure to public fracking panels in Nova Scotia and New Brunswick with one sentence: “I believe you have received answers from both agencies.”

In a recent interview on the subject of leaky wellbores, Dusseault said that he views himself as a moderate voice in the contentious fracking debate.

Unlike the Shale Resource Centre, an industry lobby group, the professor does not support a laissez faire approach to the technology and supports strong groundwater protection. In contrast to opponents of the brute force and invasive technology, Dusseault does not favor a moratorium.

He recently told a Newfoundland audience that hydraulic technology is “ill understood and my job, as much as I can, is to try to overcome that.”

Dusseault recently recommended that regulators require “multi-level groundwater monitoring” at hydraulic fracturing sites, something no energy regulator in Canada now mandates.

He also serves as a science advisor to the Alberta government on issues such as cap rock integrity and holds a total of 10 engineering patents.

[Refer also to:

January 2014: Professor Dusseault’s position on fracking met with criticism ….Dusseault looked more at the actual practice. He said it’s a practice that, if done properly, can be done safely. He also disputed information to the contrary. … “You can’t stop it from happening.”

August 2013: Fracking debate goes on or “The pot calling the kettle black”

[Dusseault] also says industry would have to provide transparent information about what it’s doing and seek consensus from neighbouring communities where it wants to drill.

“Industry is behind here. It has to provide transparent information, up front. ‘Here’s what we’re doing, we’re listening to your concerns, we’ll meet them as much as we can, we’ll do it the right way with quality control, with safety first, to make as little impact on your bucolic, rural environment as possible’. That’s what needs to happen.”

Council Canadian Academies Frac Panel does not disclose Dusseault’s frac patent.

New Brunswick Energy Institute that promotes fracing also does not disclose Dusseault’s patent; nor did Dr Louis LaPierre when he was Chair of it

Dr. David Wheeler’s Nova Scotia Frac Panel doesn’t disclose the patent either.

Above snaps taken July 17, 2014

2006: Bruce Jack Well Water Explosion, three men seriously injured

…

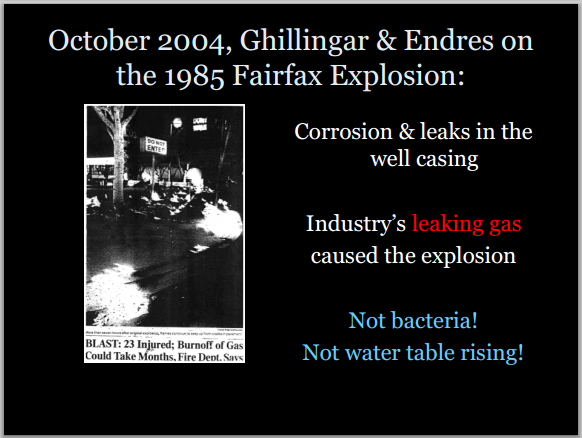

8. Ross Dress-For-Less Department Store Explosion Caused by Industry’s Leaking Methane

“Late in the afternoon of March 24, 1985, methane gas that had been accumulating ignited in an auxiliary room of the Ross Dress-For-Less Department Store … in … Los Angeles. The resulting explosion blew out the windows and partially collapsed the roof of the structure, reduced the store interior to a heap of twisted metal and resulted in injuries requiring hospital treatment of twenty-three people. Police closed off four blocks around an eerie scene of spouting gas flames that continued through the night. … The task force then went on to present a scenario of shallow ‘biogenic’ methane being displaced and pressurized by a rising water table … an imaginative explanation … Troublesome legal issues were eliminated by this conclusion, the implication being that the methane hazard could exist virtually anywhere, so no human agency was at fault for its workings.”26 [Emphasis added]

…

17. Historic Water Well Records – Alberta: Most with No Gas Present Before Oil & Gas

Maurice Dusseault, a prominent Canadian oil and gas industry researcher and gas migration expert, reported in 2002 that leaking methane gas from thousands of resource wells posed “massive environmental problems” because the escaping methane “changes the water, and generates aquifer problems.”122 Dusseault explained in an Alberta report on heavy oil that, “all unplugged wells will leak eventually, and even many wells that have been properly abandoned” would also leak gas up to surface outside of the well casing posing a hazard to groundwater and the atmosphere.123

…

33. Bainbridge Home Explosion Caused by Water with Less Methane than at Rosebud

A 2008 regulator report summarized the contamination of Bainbridge, Ohio water wells with methane leaking from a recently fractured energy well with faulty casing. The fugitive methane caused an explosion seriously damaging one home and required the evacuation of 19 others.

The company immediately assumed responsibility, provided temporary housing and “disconnected 26 water wells, purged gas from domestic plumbing/heater systems, installed vents on six water wells, plugged abandoned in-house water wells, plumbed 26 houses to temporary water supplies, provided 49 in-house methane monitoring systems for homeowner installation, and began to provide bottled drinking water to 48 residences upon request.”291

The highest concentration of dissolved methane found in 79 ground water samples at Bainbridge, Ohio was 1.04 mg/l.292 The highest found by regulator sampling at Rosebud, Alberta was 66.3 mg/l (this excludes methane in the free gas).293

34. Canadian Association of Petroleum Producers Report: 1 mg/l Methane = Explosion Risk

…

A 2009 regulator report summarized 64 gas migration cases in 22 counties in Pennsylvania dating from the 1990’s to 2009 caused by the oil and gas industry; five cases were caused by hydraulic fracturing that contaminated numerous wells and two springs used as domestic water supply.302 The 64 cases resulted in 11 explosions, five fatalities, three injuries, a road closure, and numerous evacuations with residents in one community displaced for two months.

The problem is more common than regulators like to admit.303

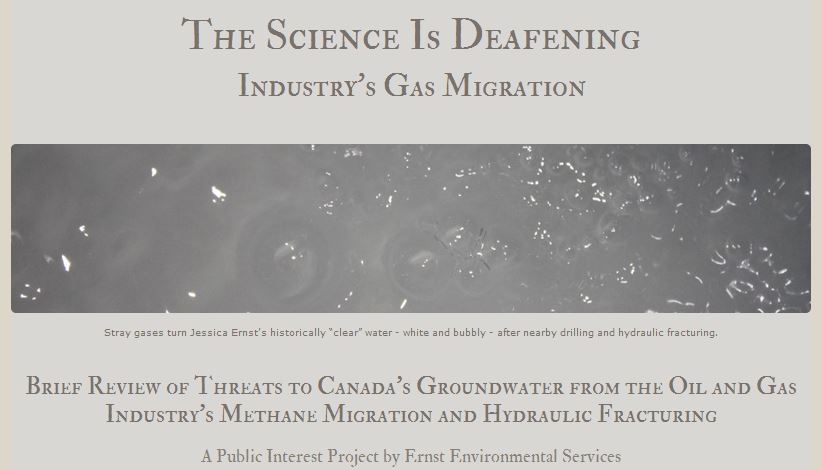

Slide from Ernst presentations

Slide from Ernst presentations