Canadian Company Gasfrac Tests Waterless Fracking in Texas by Mark Whittington, March 27, 2013, Yahoo!

As early as 2011, according to an article published by First Enercast Financial, oil and gas drillers started to recognize that they might have a problem because of a shortage of water. The problem is exacerbated because the unique geology of the Eagle Ford formation, where Texas gets much of its shale oil and gas, requires more water to frack open the product. … The Texas Tribune reports that a new technology, dubbed “waterless fracking,” may address the problem of water use in fracking operations. A Canadian company called GasFrac is using a combination of gelled propane and butane to conduct fracking, without the use of water. The technology is new and may cost more than conventional hydraulic fracking. … While the process requires a lot of propane and is said to be less effective than water in deep formations, propane is readily available in south Texas and also has the advantage that it is less likely to damage shale formations than water. … An article in Scientific American discusses environmental issues involving waterless fracking. Waterless fracking produces less wastewater, which is a positive environmental advantage over conventional fracking. However since water is used to produce and liquefy propane, the overall water savings for the process are unclear. Propane, being an explosive chemical, does pose some safety issues, though GasFrac claims that it has multiple safety protocols. GasFrac also uses proprietary chemicals to make propane into a gel, which will likely anger environmentalists who are already concerned about ground water contamination alleged to happen during conventional fracking. [Emphasis added]

Waterless Fracking Makes Headway in Texas, Slowly by Kate Galbraith with contribution by Terrence Henry , March 27, 2013, State Impact

“We don’t use any water,” said Eric Tudor, a Houston-based official with GasFrac, a Canadian company that fracks with propane geland butane. “Zip. None.” At a GasFrac operation in South Texas last month, a sticker on one worker’s hard hat showed a red slash through the word H2O. Water-free fracking still remains an early-stage technology, with potentially higher initial costs than conventional fracking methods. But as lawmakers and oil regulators focus on the large quantity of water used for fracking wells, the concept is getting a closer look. “We’ve looked at [propane fracking], and I would say that absolutely our industry is open to all possibilities,” said Michael Dunkel, the director of sustainable development for Pioneer Natural Resources, in testimony last month before a joint hearing of the House Energy Resources and Natural Resources committees. Waterless fracking is “a viable technology for sure,” said David Yoxtheimer, an extension associate with the Marcellus Center for Outreach & Research at Penn State University. However, he noted, there is a reason that companies use water, namely that it is “virtually incompressible” and thus is very effective in bringing pressure against, and ultimately breaking up, rock.

Currently there are no special rules on fracking with propane or other nonwater liquids in Texas, according to Christi Craddick, one of three members of the Railroad Commission of Texas, which regulates the oil and gas industry. The technology is “exciting” but still rare, she said, and no rule changes are on the horizon. “We’ll see as the technology evolves if our rules need to evolve,” Craddick said last week in an interview. Tudor, of GasFrac, said his company began working in Texas in 2010, after fracking its first well in Canada in 2008. It has done roughly 100 fracks in Texas so far, he estimated. (Some wells get fracked multiple times.) Much of the work has been in South Texas. A recent job bored into the San Miguel formation, which is a relatively shallow formation in the vicinity of the Eagle Ford Shale. But GasFrac has also done “a couple of prototype fracks” in West Texas, he said. “We’re just getting started,” Tudor said. Academics see a number of challenges associated with propane fracking, which few if any companies are experienting with in Texas, apart from GasFrac. First, according to Yoxtheimer, “you’ve got to truck in a lot of propane,” which can be expensive. He also said the propane “works less effectively in deeper formations where you need to build up more pressure.” Tudor disagrees that these issues pose problems. He pointed out that the virtually all the propane — which is a byproduct of natural gas processing and oil refining — gets reused. Supplies of propane come from Corpus Christi, he said, and the fuel is “easily available” in South Texas. “We won’t cause any shortages,” he said.

That is an implicit contrast with the considerable water needs of conventional fracking, which already accounts for a double-digit percentage of water use in some rural Texas counties. The water leftover from fracking operations typically does not get reused. Instead, it gets discarded into a disposal well. (The Texas Railroad Commission on Tuesday approved rules to make it easier for companies to recycle water.) Tudor also said that his company had fracked at depths well over 10,000 feet. An advantage of propane fracks, said Yoxtheimer, is that they avoid the damage to the oil and gas-producing formation that water can cause. “If you’re using water, the water can actually block off or at least impede the flow of hydrocarbons,” he said. … David Burnett, research coordinator at the Department of Petroleum Engineering at Texas A&M University, said that more study is needed. Evidence that the wells fracked with propane are more productive is “sort of anecdotal data,” he said. As for the risks of handling flammable material like propane, “Our industry is used to handling high-pressure gas and pumping flammable liquids,” Burnett said. “It’s not an issue if the equipment is designed properly.” The risks, he added, are “no more worrisome than a propane tank on the edge of town.” Tudor said that his company had done 2,000 or more fracks by now, with only one “minor incident in Canada” in which a worker got blisters while some equipment was being shut off. [Emphasis added]

[Refer also to:

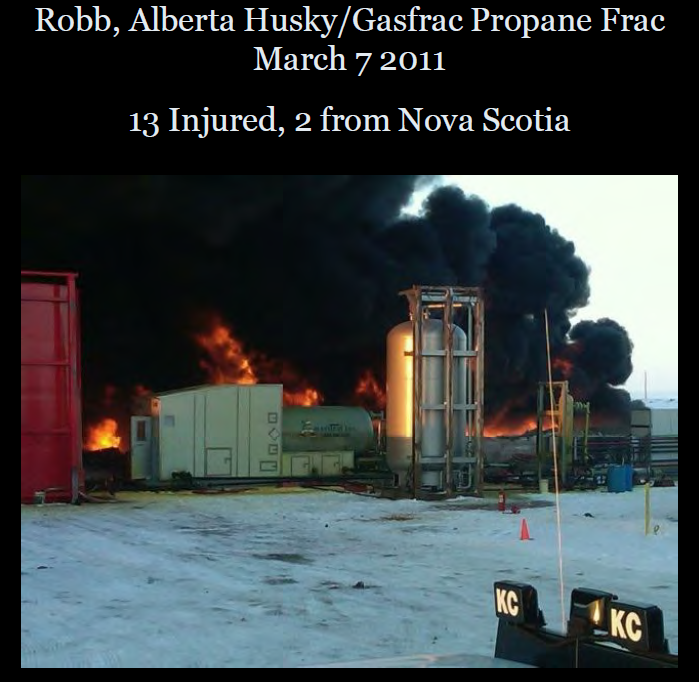

Slide from Ernst Presentation UK / Ireland 2013 Frac Speaking Tour

Oil workers suffer burns in blast by Canada’s Occupational Health and Safety Magazine, March 2011

Three GASFRAC Energy Services Inc. employees were transported to an Alberta hospital with burn injuries following an explosion and fire on January 14 [2011]. At about 5:30 pm, the employees of the Calgary company were performing gas fracturing – a process that stimulates the production of oil and gas – on a wellsite near Edson, Alberta, when a fire broke out, says Barrie Harrison, a spokesperson for Alberta Employment and Immigration in Edmonton. The site is owned by prime contractor Husky Energy Inc. The propane leak was quickly contained, although the resulting fire damaged the back end of two fracturing pumpers, reports James Hill, chief financial officer of GASFRAC. Of the employees who suffered burn injuries, two were released from hospital and the third remained with second-degree burns to his hands, Hill notes. As a precautionary measure, “GASFRAC has suspended operations until the root cause of the leak has been identified and necessary corrective actions initiated,” notes a company statement. Harrison said following the incident that two orders had been issued: a stop-work order to Husky Energy for work at the site; and a stop-work order to GASFRAC for its gas fracturing equipment.

Husky well fire injures several Alberta workers by Nathan Vander Klippe with files from Josh Wingrove, March 7, 2011, The Globe and Mail

About a dozen workers were injured after a “flash fire” burst out from an Alberta natural gas well owned by Husky Energy Inc. RCMP reported that 12 workers were hurt, with two evacuated to hospital by helicopter. Officials with Alberta Occupational Health and Safety said the number may be closer to eight, although investigators were to arrive on site Monday afternoon to determine exact specifics. No deaths have been reported, although three people were sent to an Edmonton burn unit. … Bob Curran, a spokesman with the Energy Resources Conservation Board, said the fire burst out as workers were setting up to begin the underground fraccing. Mr. Curran said the well was to be fractured using propane, a technique that has already injured three other workers this year. In January, Gasfrac Energy Services Inc. said a propane leak at one of its work sites created a “short fire.” The company suspended all operations for more than two weeks as it sought to figure out what went wrong.

Stock slides as GasFrac parts ways with top managers, Waterless well stimulation company promises to repair financial woes September 11, 2012

Canadian authorities: Fracking operation contaminated groundwater ]